How Banana Rollers Improve the Durability and Functionality of Conveyors

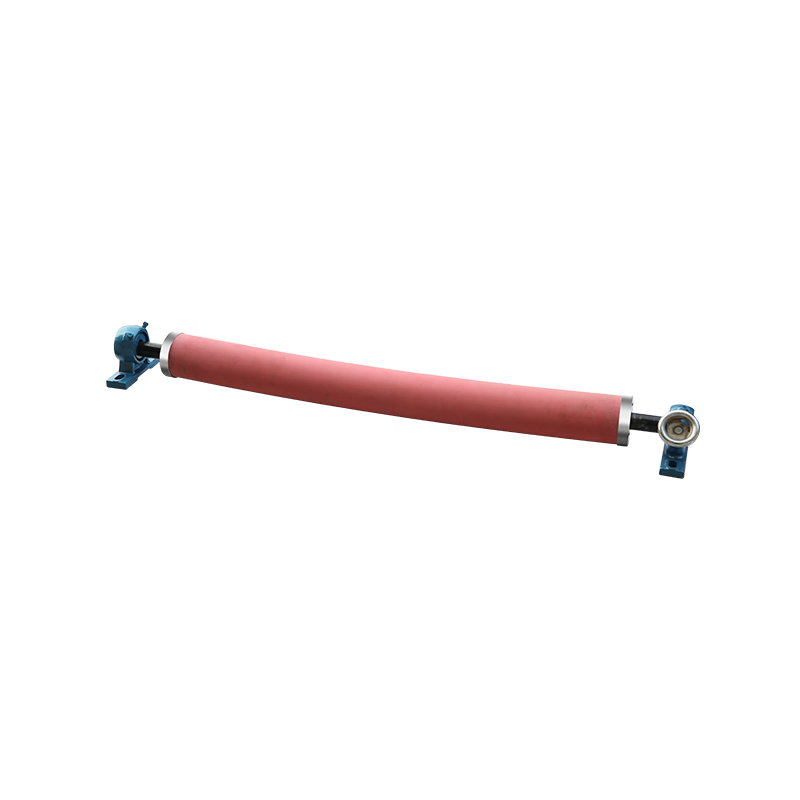

Banana rollers, named for their distinctive curved shape, are designed to support conveyor belts as they navigate around curved paths. Their curved design allows them to maintain proper alignment with the belt, providing contact and reducing wear and tear on both the rollers and the belt. These rollers are typically used in systems that require a bend or turn, ensuring that materials are transported efficiently without any disruption to the flow.

Enhancing Conveyor Durability: Reduced Wear and Tear: One of the primary advantages of banana rollers is their ability to minimize friction and prevent excessive wear on the conveyor system. The curved shape allows the rollers to better align with the curve of the conveyor track, ensuring that the belt maintains consistent tension and does not experience uneven stress. This reduces the likelihood of belt slippage, stretching, or other forms of damage, thereby extending the overall lifespan of the system.

Improved Material Handling: Banana rollers are designed to handle a wide variety of materials efficiently, ensuring smooth transportation even around tight corners. Their ability to maintain proper alignment with the conveyor belt helps prevent materials from misaligning or falling off, which can be a common issue with straight rollers when dealing with curved paths. As a result, banana rollers contribute to the continuous and stable transport of goods, which is essential for maintaining operational efficiency.

Enhanced Load Distribution: The design of banana rollers helps evenly distribute the load across the conveyor system. This is particularly important in applications where materials are heavy, irregularly shaped, or prone to shifting during transit. By distributing the load evenly, banana rollers reduce the risk of localized wear on the conveyor belt and other components, ultimately enhancing the system's longevity and preventing the need for frequent repairs.

Improving Conveyor Functionality

Optimized Conveyor Speed: By reducing friction and maintaining a smooth path for the conveyor belt, banana rollers contribute to more efficient belt movement. This can result in improved conveyor speeds, which is especially beneficial in high-speed production lines or material handling systems that require quick and consistent transport. Enhanced efficiency ensures that operations can run at their full capacity without experiencing slowdowns due to conveyor issues.

Increased Flexibility in Design: Banana rollers enable greater flexibility in the design of conveyor systems. Their unique curvature allows for more compact, efficient layouts, especially when space constraints or specific material handling needs are a concern. These rollers can be used in applications that require the conveyor to navigate complex paths or sharp turns without compromising functionality. This versatility is ideal for systems that need to move materials through tight spaces or around intricate production environments.

Lower Maintenance and Operating Costs: Banana rollers are designed to reduce friction and minimize wear, which leads to less frequent maintenance and fewer repairs. This not only improves the overall reliability of the system but also results in cost savings for businesses by reducing downtime and the need for component replacements. With less maintenance required, companies can focus more on optimizing their production processes rather than dealing with the challenges associated with conveyor malfunction.

Why Choose Banana Rollers for Your Conveyor System?

Durability: The curved design and high-quality materials used in banana rollers help reduce the wear and tear typically seen in traditional straight rollers, making them a more durable choice for long-term operations.

Efficiency: By maintaining proper alignment and reducing friction, banana rollers contribute to smoother conveyor belt movement, leading to more efficient material handling processes.

Customization: Banana rollers are available in various sizes and materials, allowing you to tailor them to your specific conveyor system needs. Whether you need them to handle heavy materials, operate in environments, or fit into tight spaces, banana rollers provide a customizable solution.

Why Choose Chuangbo Banana Rollers

Choosing Chuangbo Banana Rollers brings several key advantages that make them a top choice for industries requiring reliable and precise material handling. Here are the reasons why you should choose Chuangbo Banana Rollers:

Superior Tension Control: Chuangbo Banana Rollers are designed to offer even tension distribution across a variety of materials, ensuring consistent handling without wrinkles, misalignment, or damage. This is crucial for high-quality outputs in industries like printing, packaging, and slitting.

Durable Construction: Built from high-quality materials like steel or aluminum alloys, Chuangbo rollers are engineered for long-lasting performance. Their robust construction ensures they can withstand the rigors of demanding environments, providing a reliable solution that reduces the need for frequent replacements.

Minimized Downtime: Thanks to their efficient design and easy integration, Chuangbo Banana Rollers help reduce production delays, improving the overall efficiency of your operation. Their durability and smooth operation keep your machinery running with minimal interruptions.

Customization: Chuangbo offers customizable specifications to meet your unique needs, ensuring that the roller fits perfectly with your equipment and process requirements. Whether you need a specific size or feature, we provide tailored solutions to optimize your production.

ISO Certified: As a trusted manufacturer, Chuangbo's ISO-certified products meet high industry standards, guaranteeing quality, safety, and performance that you can depend on.

Global Shipping & Bulk Discounts: We provide fast global shipping and bulk-order discounts, making it easy and cost-effective to get the equipment you need, wherever you are.

Banana rollers are an integral part of optimizing the durability and functionality of conveyor systems, particularly in environments where the conveyor must navigate turns or curved paths. Their ability to minimize wear, distribute loads evenly, and ensure smooth, efficient operation makes them a choice for industries that rely on conveyor systems for material handling. By incorporating banana rollers into your system, you can improve overall efficiency, reduce downtime, and extend the lifespan of your equipment, leading to long-term cost savings and enhanced operational performance.