Understanding Differential Air Shafts: Precision Tension Control for Industrial Applications

Differential air shafts play a pivotal role in this process by offering a unique solution for managing tension while ensuring smooth handling of material rolls. These devices are particularly valued for their ability to regulate tension during the winding and unwinding of materials, providing a reliable and efficient way to optimize production operations.

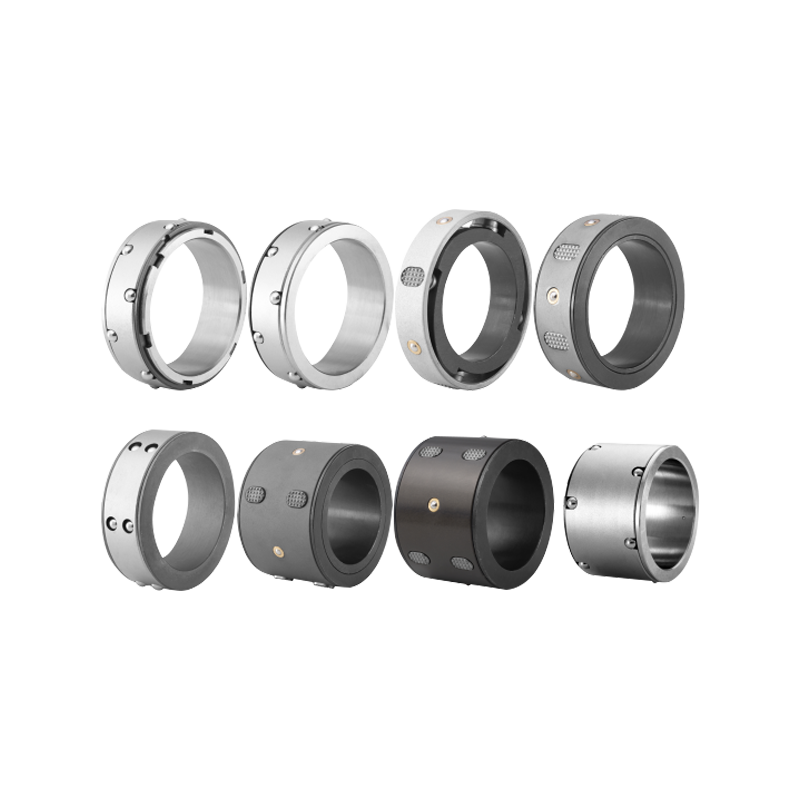

A differential air shaft is a specialized type of shaft that integrates a unique air-driven mechanism to provide precise and consistent tension control during material processing. Unlike conventional air shafts, which offer uniform expansion and contraction, a differential air shaft uses a differential mechanism that allows for controlled tension differences across the material roll, thereby optimizing the winding and unwinding process.

The differential mechanism allows each segment of the air shaft to react independently to the material's tension. This means that the roll's inner layers and outer layers can be controlled differently, ensuring that consistent tension is maintained across the entire roll, even as the diameter changes. This is particularly beneficial when dealing with materials of varying thicknesses or uneven rolls, which often occur in high-speed applications.

What Makes Differential Air Shafts Different?

Unlike conventional air shafts, which provide uniform tension across the roll, differential air shafts are engineered to adjust the tension at different sections of the material roll independently. This differential tensioning allows for greater precision in applications where the material is sensitive to variations in tension, such as in printing presses or textile production.

The core mechanism of a differential air shaft involves the differential air pressure applied to different segments of the shaft. By varying the pressure in individual sections, the shaft adjusts the amount of grip applied to the core of the roll, allowing for tension management that adapts to the material's specific needs. This innovative design ensures that materials are processed with consistent tension, regardless of changes in roll diameter, material type, or environmental conditions.

How Differential Air Shafts Benefit Specific Industries

Printing Industry: In printing presses, where high-quality prints must be achieved consistently, differential air shafts are used to regulate the tension on rolls of paper, film, or flexible substrates. By controlling the tension, these shafts ensure that printing occurs without distortion, maintaining sharp details and color accuracy.

Textile Manufacturing: Textile production involves delicate fabrics that can easily be damaged by uneven tension. Differential air shafts ensure smooth handling of fabrics during processes like weaving, spinning, and dyeing, providing consistent tension that prevents wrinkles or material deformation.

Packaging: Packaging lines often use plastic films or cardboard rolls that require consistent tension to ensure efficient wrapping or sealing. Differential air shafts optimize tension control in packaging machinery, preventing errors in sealing or alignment and enhancing the efficiency of the production process.

Plastics Processing: In plastics manufacturing, where materials such as plastic films or sheets are wound or unwound in large quantities, differential air shafts help control tension and prevent issues like film breakage or stretching. The ability to maintain uniform tension improves material handling and results in higher-quality plastic products.

Applications of Differential Air Shafts

Differential air shafts are used across various industries where consistent and precise tension control is essential for material handling:

Printing Industry: In printing presses, where maintaining even tension on large rolls of paper and film is critical for ensuring high-quality printing results.

Packaging: Used in packaging lines to control tension during the winding and unwinding of materials like plastic film or cardboard rolls.

Textile Manufacturing: Ideal for handling textile rolls, ensuring smooth processing without causing damage or tension-related issues.

Plastics Manufacturing: Differential air shafts are used in plastic film production and extrusion lines to manage the consistent handling of films and sheets.

Converting Applications: In slitting and rewinding machines, where precise control over tension can prevent defects in the material.

Why Choose Differential Air Shafts from Ruian Chuangbo Machinery Co., Ltd.?

At Ruian Chuangbo Machinery Co., Ltd., we provide high-quality differential air shafts designed to deliver performance in tension control and material handling. Our products are engineered to meet the specific needs of various industries, offering:

Superior precision and consistent tension control to improve product quality.

Durability and long-lasting performance in high-speed, high-demand environments.

Low-maintenance design that reduces operational costs and improves system reliability.

Customization options to meet the unique needs of each application, ensuring performance.

By integrating differential air shafts into your production line, you can improve product quality, reduce waste, and maximize efficiency. Contact us today to learn more about how our products can enhance your material handling systems and optimize your operations.