Mechanical Expand Chucks: A Critical Component in High-Precision Material Handling Systems

In modern manufacturing environments, the need for precision, efficiency, and reliability has never been greater. One crucial component that plays a significant role in achieving these goals is the mechanical expand chuck. These devices, which are designed for use in material handling systems, offer unparalleled control over tension and torque, enabling manufacturers to maintain high-quality standards throughout production.

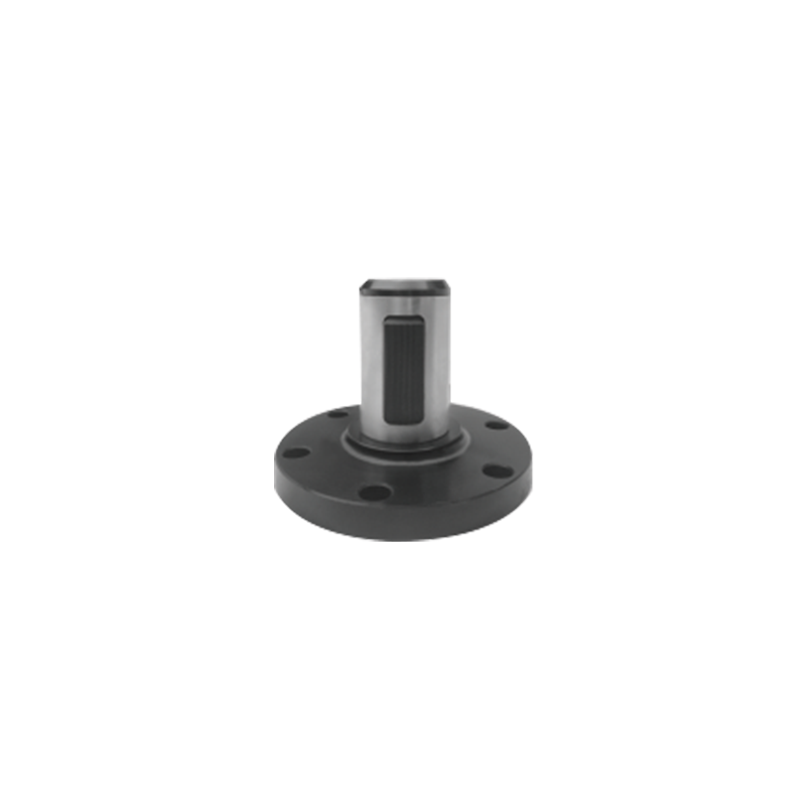

A mechanical expand chuck is an advanced clamping device designed to hold cylindrical or tubular materials securely in place, using an expanding mechanism. Unlike traditional clamping systems, which may apply uniform pressure across the material, mechanical expand chucks expand radially to grip the material from the inside. This mechanism ensures a balanced, secure hold, even for materials that require gentle handling to avoid damage.

Primarily used in industries such as printing, aerospace, automotive, and metalworking, mechanical expand chucks provide an indispensable solution for processes requiring high levels of accuracy. They are integral in applications where rotation, tension, and material integrity must be controlled with precision.

The Strategic Importance of Mechanical Expand Chucks in Manufacturing

Mechanical expand chucks are pivotal in applications where precision and minimal material deformation are paramount. These chucks offer distinct advantages in industries that require high levels of accuracy in their material handling processes:

Printing and Packaging: Mechanical expand chucks are widely used in roll-to-roll printing and packaging lines, where they securely hold rolls of paper, film, or textiles. The precise tension control provided by these chucks ensures that the material is fed smoothly through printing or packaging equipment, preventing wrinkles, misalignment, or uneven distribution.

Metalworking and Machining: In industries such as automotive, aerospace, and heavy machinery manufacturing, mechanical expand chucks help hold materials like metal rods, tubes, and bars during operations like turning, milling, and grinding. Their ability to maintain a strong grip while preventing material distortion makes them ideal for these applications, where even slight inaccuracies can lead to significant product defects.

Textile Manufacturing: Mechanical expand chucks are also used in the textile industry, where they provide consistent tension control during weaving, knitting, or dyeing processes. This ensures that the fabric is processed evenly, reducing defects such as uneven stretch or fabric puckering, which can occur with traditional clamping systems.

Why Mechanical Expand Chucks Are Critical in High-Precision Material Handling

The ability to handle materials with absolute precision is a cornerstone of modern manufacturing. Mechanical expand chucks are integral to achieving this precision by providing a secure, stable grip that ensures materials remain in place during processing, even under varying loads or tension. This is particularly important in industries where minor deviations from the specified dimensions can compromise product quality, safety, or functionality.

Additionally, these chucks improve operational efficiency by minimizing material waste and defects. The even clamping force prevents materials from being over-pressed or damaged, reducing scrap and rework costs. This is crucial in industries that handle expensive or scarce materials, where the cost of waste can be significant.

Selecting the Right Mechanical Expand Chuck

Material Compatibility: The chuck must be compatible with the specific material being processed. Whether it's metal, plastic, or textile, the chuck's design and material composition should align with the properties of the material to prevent damage during handling.

Clamping Range: The chuck should accommodate a variety of material sizes within the required clamping range. A chuck with a broad adjustment capacity offers flexibility, but it's essential that the chuck still provides a secure, uniform grip at all settings.

Tension Control: For processes that involve tension, such as in printing or textiles, the chuck should allow for precise control over material tension. This is particularly important when working with sensitive materials that require a consistent, uniform stretch.

Environmental Considerations: Consider the operating environment when selecting a chuck. Exposure to temperatures, humidity, or corrosive chemicals can impact the chuck's performance. Choosing a chuck designed to withstand these factors ensures reliable operation over time.

Mechanical expand chucks are indispensable in high-precision material handling systems, offering a blend of flexibility, reliability, and accuracy. Their unique expanding mechanism ensures that materials are held securely and evenly, minimizing the risk of defects or material damage during processing. By selecting the appropriate mechanical expand chuck for specific applications, manufacturers can significantly enhance production efficiency, maintain high-quality standards, and reduce operational costs.