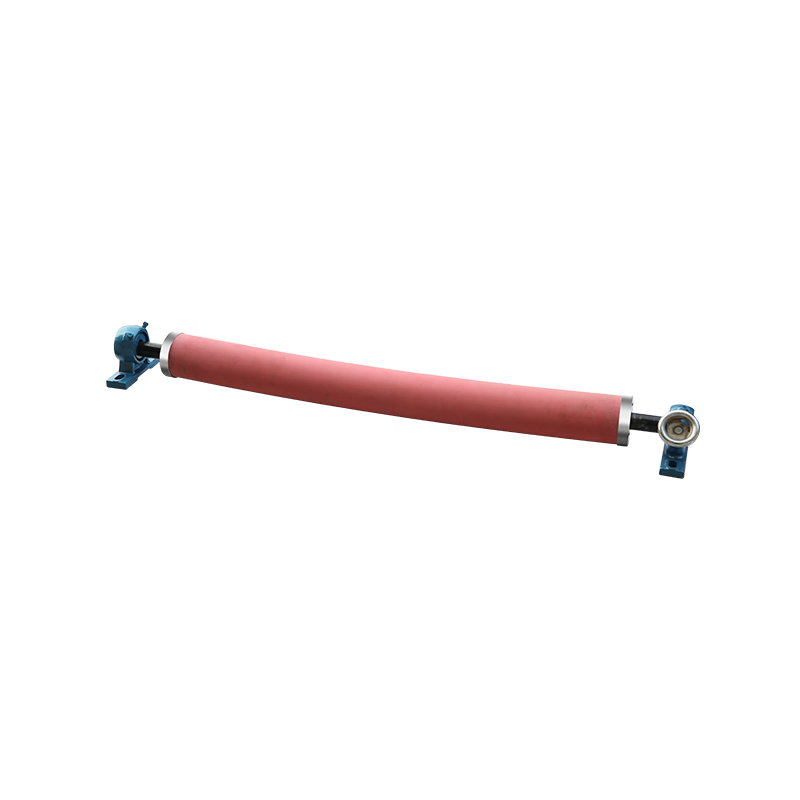

What is an Expanding Air Shaft?

An Expanding Air Shaft is a mechanical device used primarily in the winding and unwinding of materials, such as paper, plastic films, textiles, metal foils, and other roll-based products. The shaft is equipped with an air-actuated mechanism that allows it to expand and grip the inner diameter of a roll of material, enabling smooth and efficient handling during the winding process.

Expanding air shafts are widely used in industries such as printing, packaging, and textiles, where precise control and secure handling of material rolls are critical. These shafts use air to expand and grip the rolls, offering improved efficiency and reducing manual labor.

They provide consistent tension control, ensuring smooth unwinding and winding, which is essential for high-precision tasks. Their versatility allows them to accommodate a variety of materials and core sizes, making them suitable for a broad range of applications.

These shafts also contribute to workplace safety by minimizing manual handling, reducing the risk of injuries. Their durability and low-maintenance design help reduce downtime and operational costs, offering a better return on investment.

With fewer moving parts, they maintain alignment and prevent material damage, ensuring consistent quality. Although the initial cost may be higher, the long-term benefits of increased efficiency, cost savings, and enhanced product quality make these tools indispensable in modern manufacturing processes.

Advantages of Expanding Air Shafts

| Benefit |

Description |

| Easy Handling |

Expanding Air Shafts allow operators to handle rolls quickly and efficiently with minimal effort, reducing downtime during material changeovers. |

| Versatility |

Compatible with a wide range of materials such as paper, film, and textiles, and suitable for various industries like packaging, printing, and textiles. |

| Improved Safety |

The expanding air mechanism ensures that rolls are securely gripped, preventing slipping or misalignment, which enhances worker safety. |

| Cost-Efficiency |

By reducing manual labor time and minimizing material wastage, Expanding Air Shafts help lower operational costs. |

| Adjustable Core Sizes |

Air shafts can be adjusted to accommodate different core sizes, offering flexibility for handling materials with varying dimensions. |

| Reduced Maintenance |

With fewer moving parts compared to traditional mechanical shafts, Expanding Air Shafts require less maintenance and offer greater reliability over time. |

CBB Guide to Choosing the Right Expanding Air Shaft

When selecting an Expanding Air Shaft, consider the following factors: Ensure compatibility with materials like paper, film, or textiles. Choose shafts that can accommodate varying core sizes for flexibility. Ensure the shaft can handle the weight and size of the rolls you work with. Decide between manual or automatic inflation based on your production needs. Look for shafts made from high-quality materials like stainless steel for long-lasting performance. Choose shafts with fewer moving parts and easy-to-replace components to reduce downtime. Evaluate the total cost, including maintenance, labor savings, and material waste reduction. Ensure the shaft has safety mechanisms like emergency release and non-slip surfaces. Opt for manufacturers offering reliable warranty and technical support. If needed, consider custom shafts tailored to your specific requirements.