How Can Centrifugal Blowers Improve Airflow Efficiency in Industrial Applications?

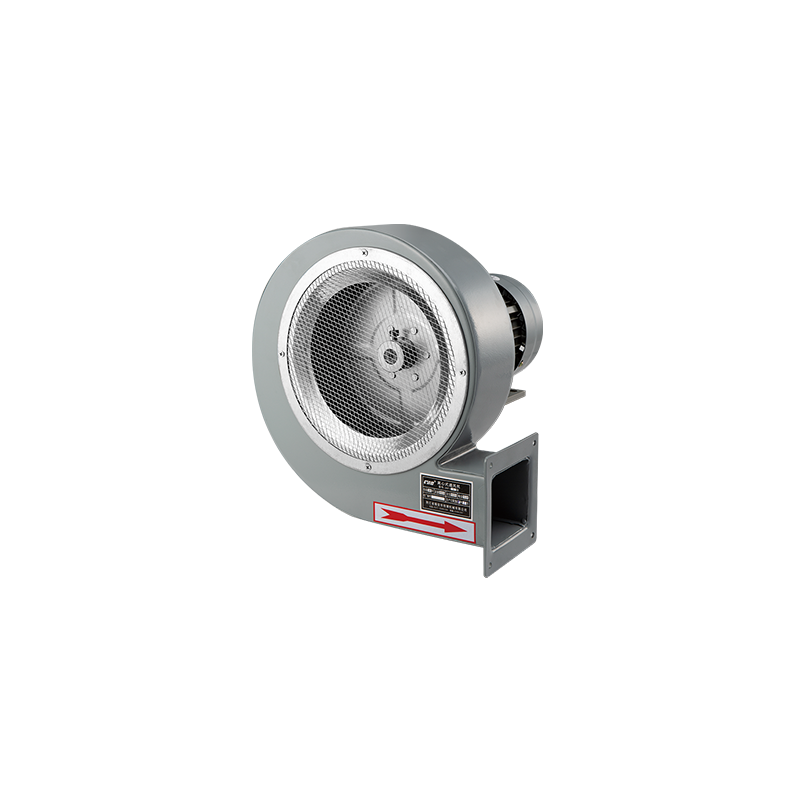

Centrifugal blowers are a critical component in many industrial applications, offering significant benefits in terms of airflow efficiency. These blowers are designed to move air or gases through a system by converting rotational energy from a motor into kinetic energy, creating a high-velocity air stream. Their design allows for a consistent flow of air at varying pressures, making them ideal for environments where both air volume and pressure control are essential.

Optimized Pressure Generation: One of the primary advantages of centrifugal blowers is their ability to generate high static pressure, which makes them highly effective in applications requiring significant resistance to airflow. This is particularly important in industrial environments where air must be moved through ducts, filters, or long distances. Centrifugal blowers excel at overcoming these resistances, maintaining consistent airflow even under varying system demands. This makes them ideal for critical systems such as air handling units, HVAC systems, and industrial exhaust systems.

Improved System Efficiency: Centrifugal blowers are designed to enhance overall system efficiency by ensuring that air is delivered at the correct pressure and volume without unnecessary energy consumption. Their ability to maintain stable airflow helps to prevent system failures or inefficiencies that could arise from inconsistent air delivery. By precisely matching the blower's performance to the requirements of the application, businesses can reduce wasted energy and optimize the performance of their machinery and equipment, resulting in significant cost savings over time.

Uniform Air Distribution: In many industrial applications, maintaining a uniform air distribution is key to process stability. Centrifugal blowers provide a consistent airflow pattern that ensures an even distribution of air across the entire system. This is essential in environments where balanced air supply is needed for processes like drying, cooling, and ventilation. The even airflow prevents hot spots, uneven cooling, and inconsistent drying, improving the quality and consistency of industrial outputs.

Adaptability to Different Applications: Centrifugal blowers offer unmatched versatility, as they can be configured to handle a wide range of airflow demands. Whether it's moving large volumes of air at lower pressure or handling smaller volumes at higher pressure, these blowers can be customized to meet the specific needs of different applications. Industries such as chemical processing, food manufacturing, and waste management all benefit from the flexible performance capabilities of centrifugal blowers. The ability to adjust blower parameters also means that they can be easily integrated into new or existing systems, improving the overall design and functionality.

Cost Savings Through Energy Efficiency: Energy consumption is one of the largest operating costs for industrial systems. Centrifugal blowers contribute to cost savings by operating efficiently and effectively, reducing the amount of energy required to move air through a system. By using advanced motor technologies and impeller designs, centrifugal blowers can deliver performance with less power, minimizing energy waste. The result is lower electricity bills and a more sustainable operation, making centrifugal blowers a cost-effective solution for industries looking to reduce their carbon footprint.

Enhanced Durability and Reliability: Centrifugal blowers are engineered for longevity and reliability. Constructed with durable materials and designed for minimal wear, they require less frequent maintenance than other types of blowers. This means less downtime, fewer repairs, and a more efficient operation overall. The rugged design of centrifugal blowers makes them well-suited to handle challenging industrial environments where high temperatures, dust, and other contaminants might be present.

Centrifugal blowers provide a range of benefits that directly contribute to improved airflow efficiency in industrial settings. Their ability to generate high pressure, maintain uniform air distribution, and operate with reduced energy consumption makes them an essential tool in optimizing industrial systems. As industries continue to prioritize efficiency and sustainability, centrifugal blowers offer a reliable solution that enhances both the performance and longevity of air systems, ensuring smoother and more cost-effective operations.