Design Considerations for Aluminum Rollers in High-Speed Conveyance Systems by Ruian Chuangbo Machinery Co., Ltd.

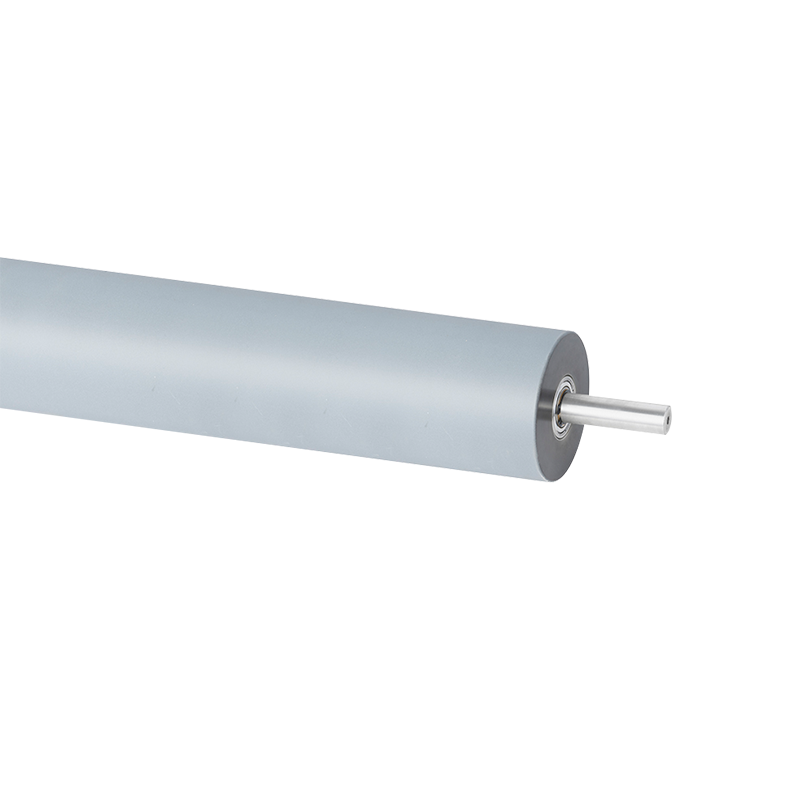

Aluminum rollers are critical components in high-speed conveyance systems, playing a crucial role in enhancing material handling efficiency across various industries, including automotive manufacturing, food processing, electronics assembly, and aerospace engineering. When designing aluminum rollers for these systems, several factors must be considered to optimize their performance, longevity, and cost-effectiveness. At Ruian Chuangbo Machinery Co., Ltd., we specialize in crafting precision-engineered rollers that meet the unique demands of high-speed applications, ensuring smooth, reliable operations.

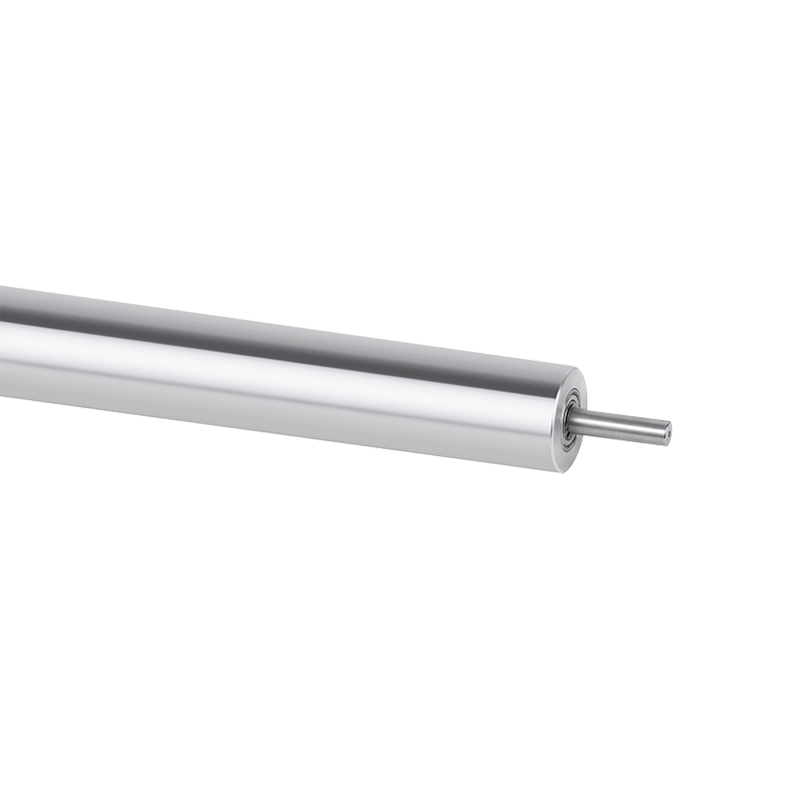

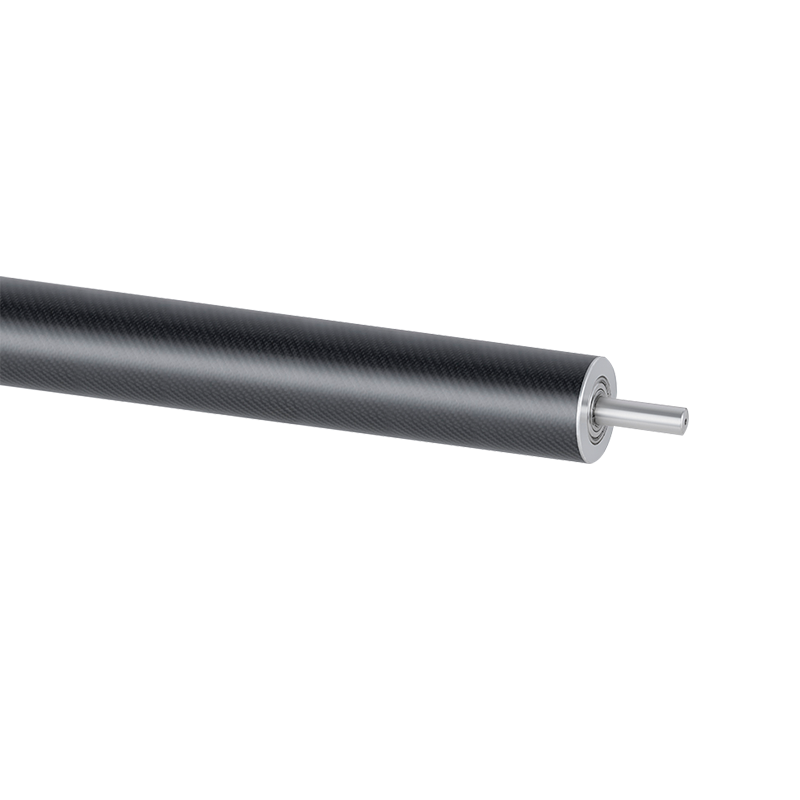

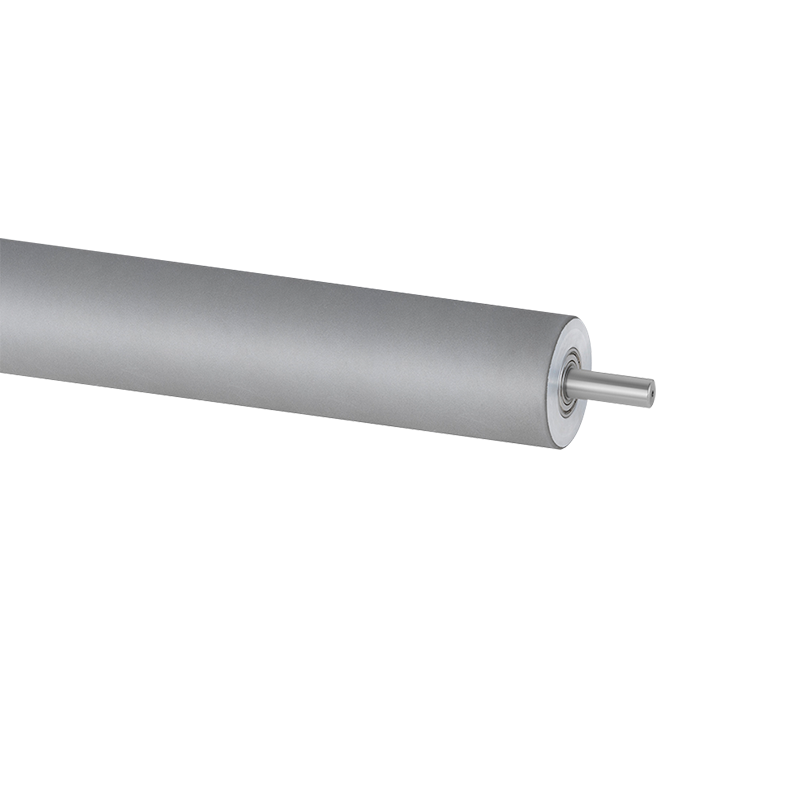

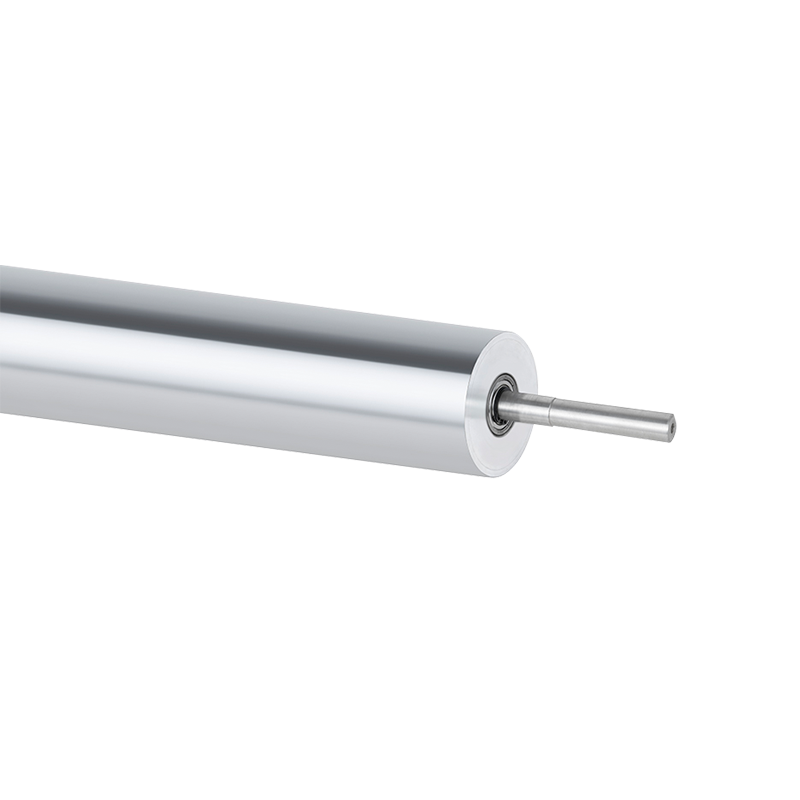

Material Selection and Alloy Composition: The alloy composition of aluminum rollers directly impacts their performance in high-speed conveyance systems. While aluminum is known for being lightweight, different aluminum alloys offer varying levels of strength, durability, and resilience. It's important to select an alloy with strength-to-weight ratios, ensuring that the rollers can handle the dynamic forces encountered during high-speed operations. For environments requiring high corrosion resistance, aluminum alloys with enhanced surface coatings or anodized finishes are often preferred. These alloys provide performance and durability under operating conditions, ensuring a longer lifespan with minimal maintenance.

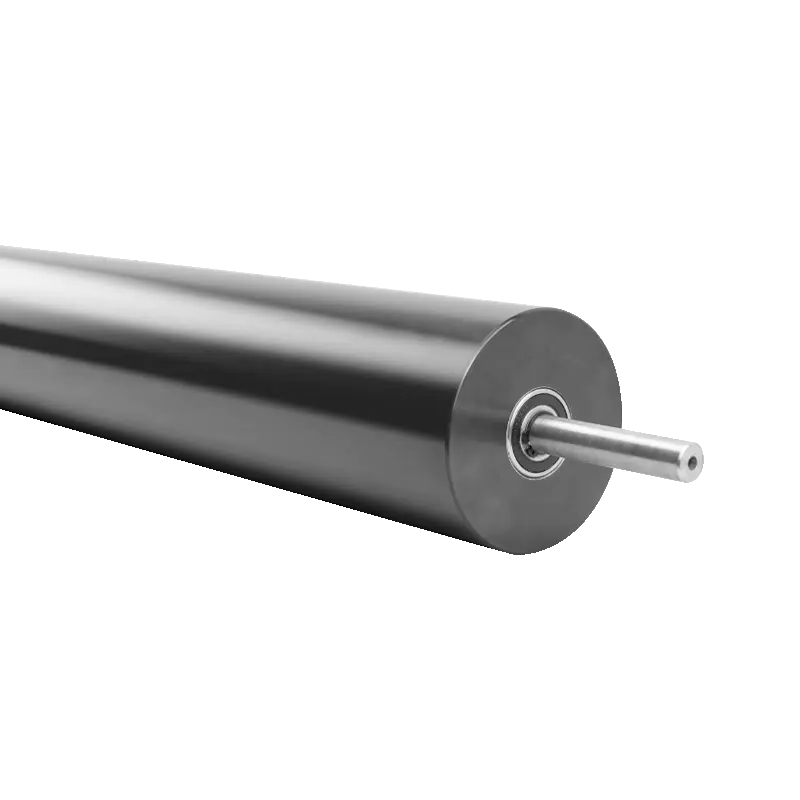

Bearing Selection and Integration: In high-speed conveyance systems, the bearing integration within aluminum rollers is critical for ensuring smooth, efficient performance. The choice of bearings must be tailored to the specific requirements of the system, factoring in load capacity, friction resistance, and durability. High-quality bearings are essential to reduce friction and ensure that the rollers operate smoothly under heavy loads, minimizing energy consumption and reducing wear over time. The design should also allow for easy maintenance and replacement of bearings to ensure continued performance without system downtime.

Roller Diameter and Weight Optimization: The diameter and weight of aluminum rollers must be optimized to balance strength with efficiency. Rollers that are too heavy can slow down the system, while those that are too light may not support the necessary load. The ideal roller diameter ensures smooth material flow and efficient load distribution across the system. For high-speed conveyance systems, minimizing the weight of the roller is essential, as it reduces the overall system load, improving speed, and decreasing the energy needed to run the system. However, the diameter and weight must be carefully balanced with the need for load-bearing capacity to ensure performance in industrial applications.

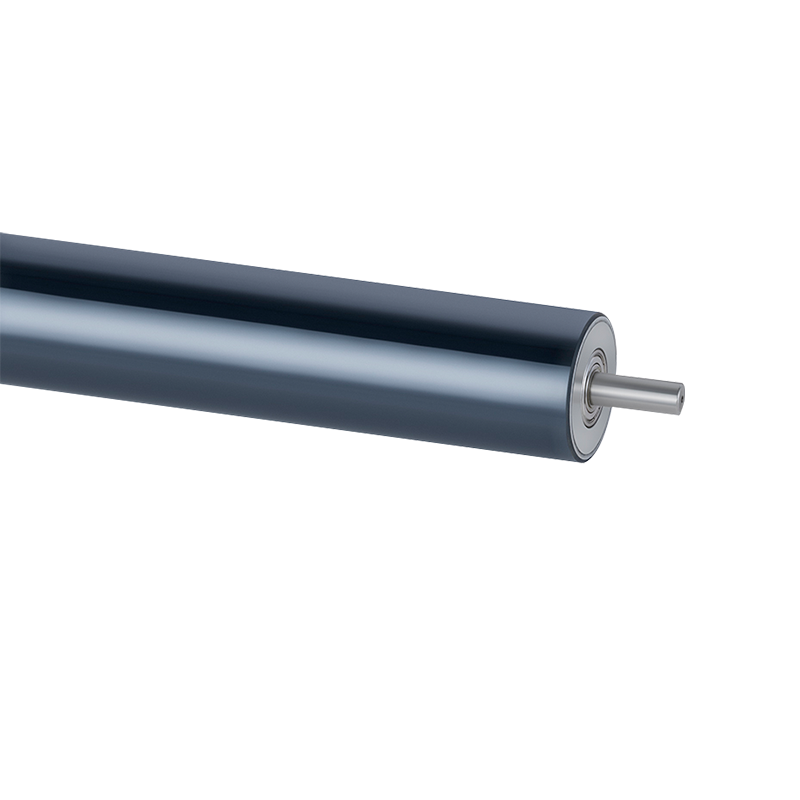

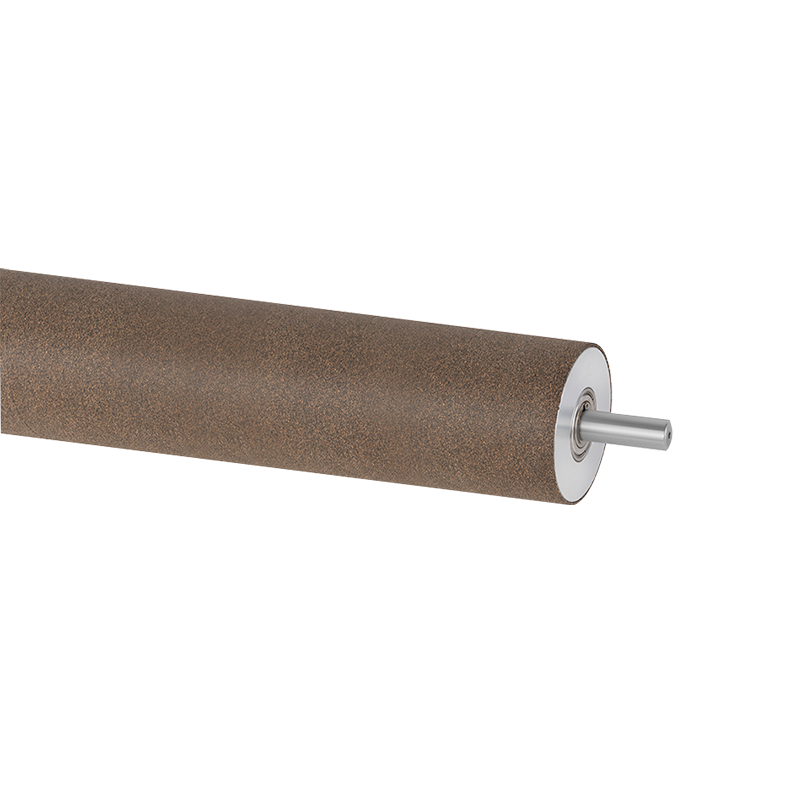

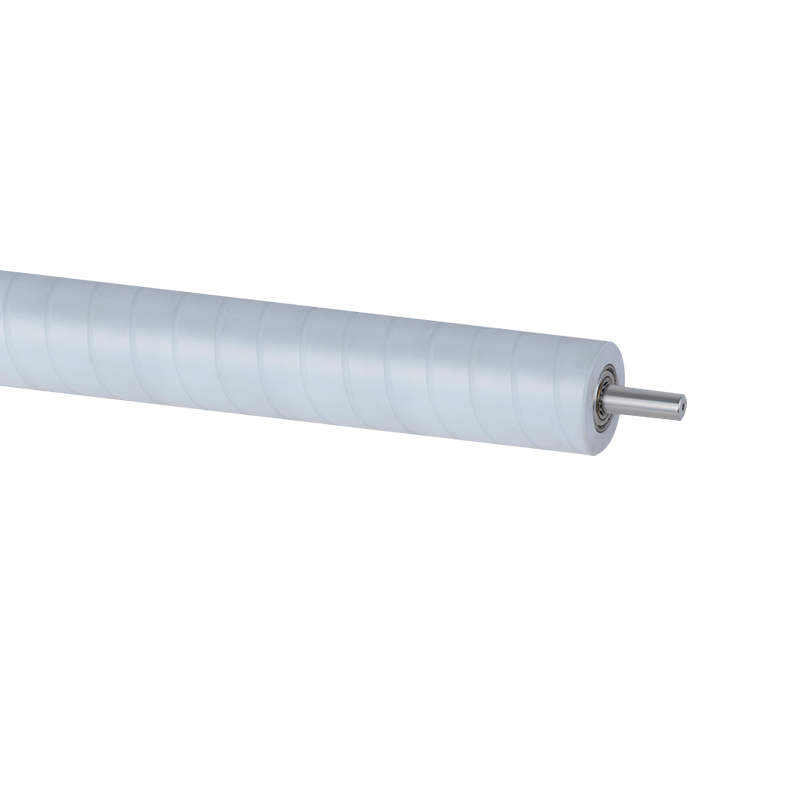

Surface Treatment and Coatings: The surface finish of aluminum rollers plays a significant role in their functionality, particularly in high-speed applications. A smooth surface minimizes friction, which is critical for high-speed conveyance systems to operate without interruptions. Surface treatments such as anodizing, hard coating, and specialized corrosion-resistant coatings can greatly enhance the abrasion resistance and chemical resistance of aluminum rollers. This is especially important in environments where the rollers are exposed to moisture, chemicals, or abrasive materials. The right surface treatment helps extend the lifespan of the rollers while maintaining consistent performance throughout the system.

Thermal Resistance: High-speed conveyance systems often operate in environments where temperature fluctuations are common. Whether in industries like aerospace, automotive manufacturing, or metal processing, rollers are subject to varying thermal conditions. Aluminum has thermal resistance, but the design of the roller should account for potential thermal expansion and contraction during high-speed operations. Selecting appropriate aluminum alloys and coatings that can withstand thermal stresses will ensure that the rollers perform reliably even in high-temperature environments, preventing deformation or failure due to thermal extremes.

Noise Reduction and Vibration Control: In many high-speed industrial environments, noise reduction and vibration control are critical for maintaining a productive and comfortable workplace. Aluminum rollers, being relatively harder materials, can generate noise when in motion. However, thoughtful design strategies such as vibration-damping components or incorporating composite bearings can help reduce the noise levels and vibrations. This is particularly important in electronics assembly and printing industries, where noise control is a high priority. Ensuring that the rollers operate smoothly and quietly contributes to worker safety, health, and overall system efficiency.

Durability and Maintenance Considerations: Rollers designed for high-speed applications are built to endure heavy loads and continuous operation under challenging conditions. Their longevity plays a critical role in ensuring cost-effectiveness. Given their exposure to abrasion, moisture, and chemical agents, choosing the right materials and design features is essential to avoid frequent repairs or replacements. Solutions like self-lubricating bearings and durable coatings significantly reduce the need for maintenance, leading to lower downtime and maintenance costs. These features, combined with robust design principles, contribute to increased system efficiency and overall productivity in demanding environments.

Customization for Industry-Specific Applications: Every industry has unique requirements when it comes to roller performance. Customizing rollers is essential to meet the specific needs of high-speed conveyance systems. Tailored elements, such as roller diameters, special coatings, and bearing configurations, ensure performance. For industries like food processing and pharmaceuticals, rollers must be designed for easy cleaning and maintenance to meet high sanitation standards and avoid contamination risks. On the other hand, industries such as automotive manufacturing demand rollers capable of withstanding heavy loads and operational conditions. Customization ensures that rollers perform efficiently and meet the demands of each specific application.

The design process for high-speed conveyance system rollers requires a deep understanding of material properties, engineering principles, and the specific operational demands of various industries. Critical considerations include bearing integration, surface treatments, roller dimensions, and thermal resistance. Balancing these factors is essential for achieving peak performance. Manufacturers like Ruian Chuangbo Machinery Co., Ltd. focus on delivering high-precision rollers that not only enhance efficiency but also provide reliability and durability. By prioritizing features like strength, low maintenance, and noise reduction, these rollers contribute to more sustainable and productive operations.

With the right engineering approach and design features, rollers can effectively meet the rigorous demands of modern high-speed conveyance systems. The result is improved performance, cost savings, and enhanced system longevity, making them an indispensable component for industries striving for efficiency and sustainability.