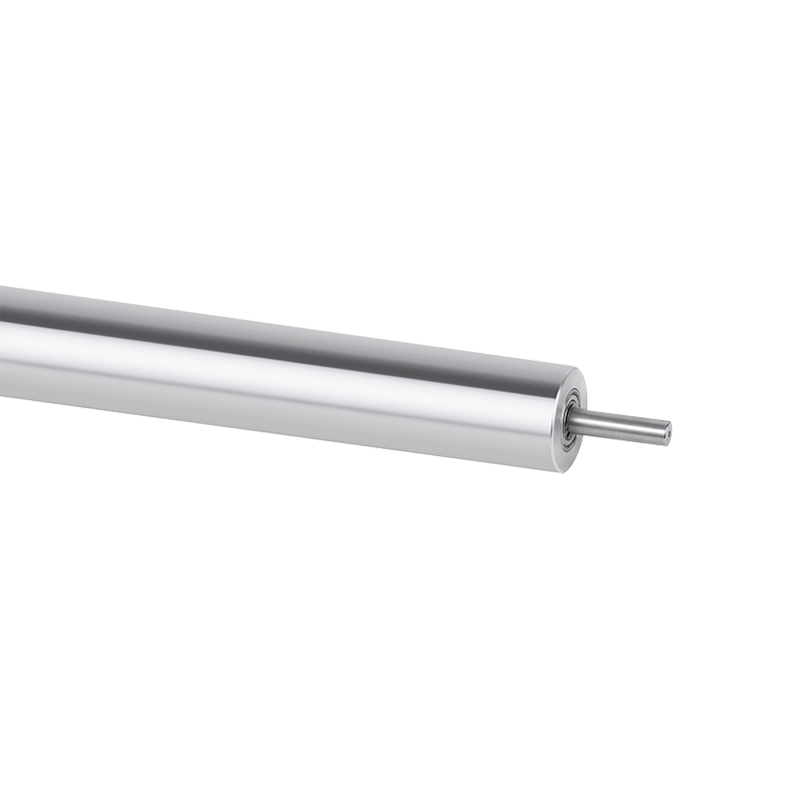

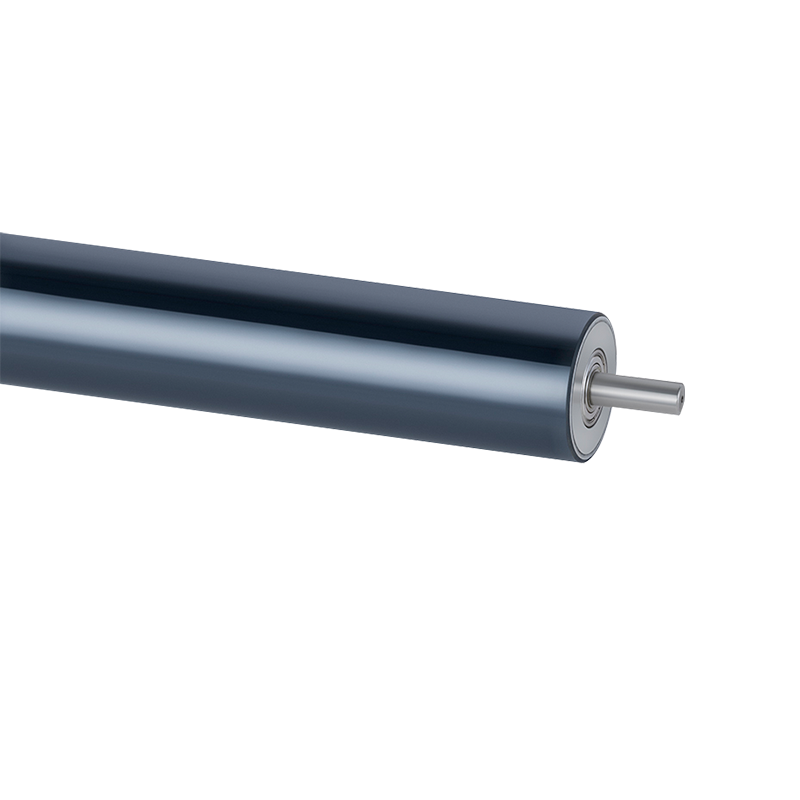

High-Performance Black Hard Anodized Aluminum Roller for Industrial Applications

The Black Hard Anodize Aluminum Roller combines advanced surface treatment technology with robust engineering to deliver exceptional durability and performance in demanding industrial environments. Featuring a sleek black finish, this roller is designed to meet the rigorous demands of industries requiring corrosion resistance, wear protection, and aesthetic appeal. Below, we explore its technical advantages, customizable features, and diverse applications across sectors.

Benefits

Enhanced Corrosion and Wear Resistance

The hard anodized coating creates a dense, black oxide layer on the aluminum surface, offering protection against moisture, chemicals, and abrasion. This makes the roller ideal for applications in marine engineering, chemical processing, or high-friction environments.

Aesthetic and Functional Surface Finish

The distinctive black finish not only enhances visual appeal but also provides a uniform, non-reflective surface. This reduces glare in precision tasks and improves material handling in applications like printing or packaging.

Lightweight and High-Strength Design

This lowers energy consumption in automated systems and simplifies installation.

Key Features

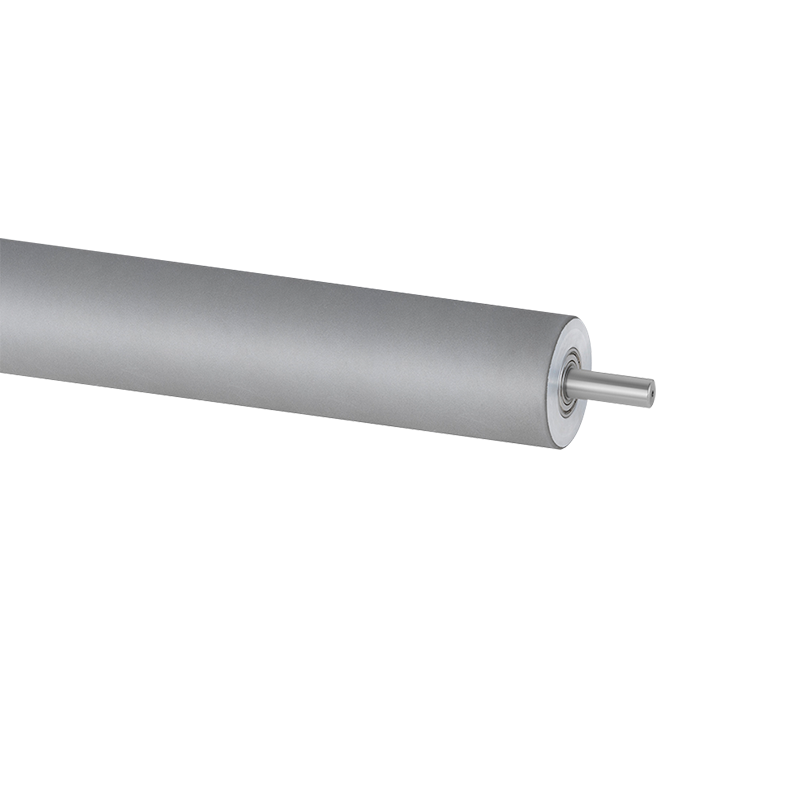

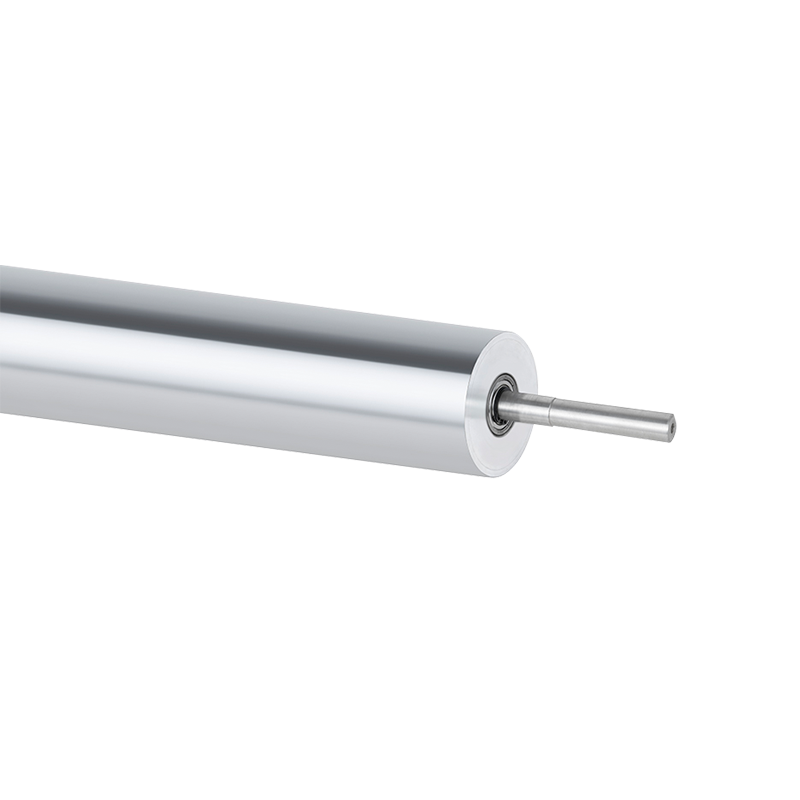

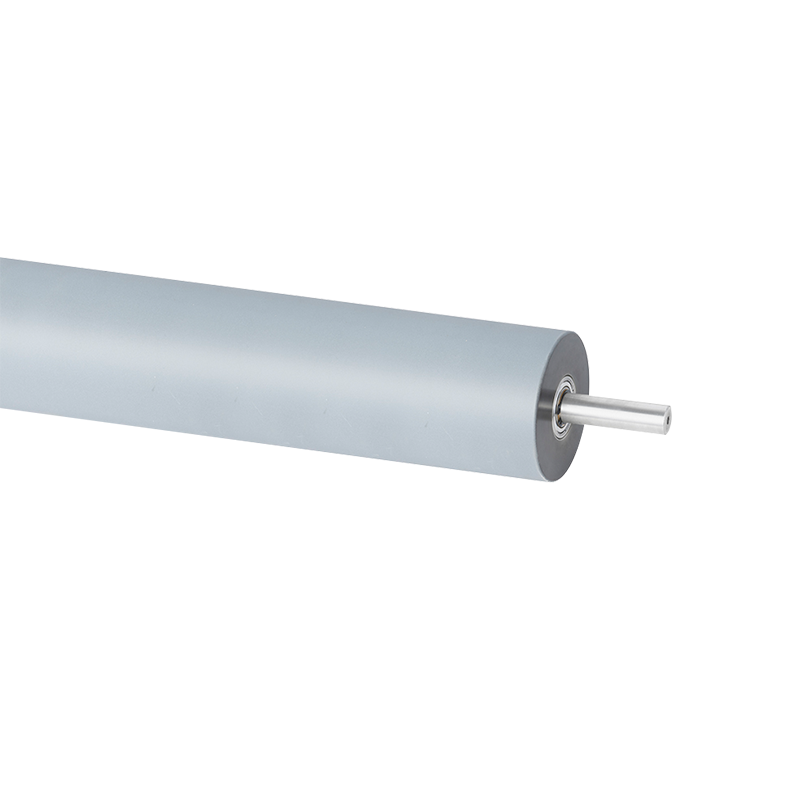

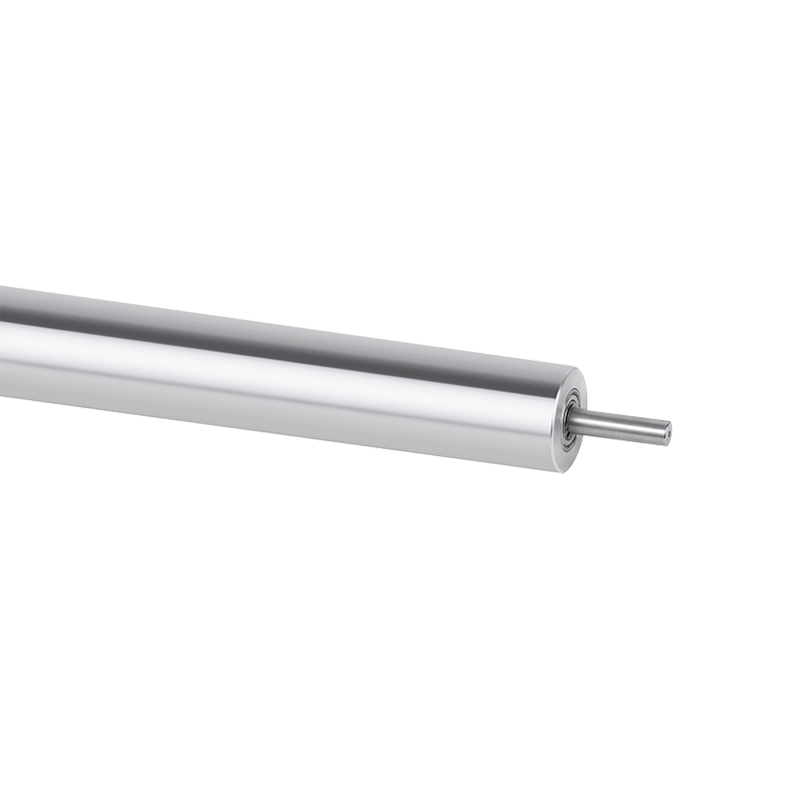

- Versatile Roller Configurations

The roller is available in four specialized designs to meet diverse operational needs:

Flat Tube Type: Ensures uniform pressure distribution for precision tasks like laminating or coating.

Without Shaft Type: Streamlines integration into compact machinery with space constraints.

Through Shaft Type: Supports high-torque operations requiring continuous rotational motion.

Shaft Type: Compatible with standard industrial setups for heavy-duty applications.

Customizable Surface Textures

Tailor the roller’s surface to optimize performance:

Polished Finish: Reduces friction for smooth material release in printing or film processing.

Textured Finish: Enhances grip in conveying systems handling slippery or irregular materials.

Anilox Line: Ensures precise ink or coating transfer for high-quality printing.

Grooved Line: Prevents slippage in material handling or packaging workflows.

Industry Applications

Printing & Packaging

The black-coated roller’s Anilox and Grooved Line textures ensure uniform ink distribution and material handling, critical for high-resolution printing and efficient packaging workflows.

Automotive Manufacturing

Used in robotic welding lines and EV battery assembly, its corrosion resistance and thermal stability enhance performance in high-temperature environments.

Aerospace & Defense

The lightweight design and durable coating make it suitable for composite layup tools and precision machining of aircraft components.

Food & Pharmaceutical Processing

The non-toxic, easy-to-clean surface meets hygienic standards, ideal for handling sensitive materials in controlled environments.

Renewable Energy

Employed in solar panel laminating systems and wind turbine production, where durability and precision are critical for long-term efficiency.

Case Study: Optimizing Efficiency in Packaging

A global packaging manufacturer integrated the Black Hard Anodize Aluminum Roller into their film-handling conveyor system. Challenges included frequent wear from abrasive materials and high maintenance costs.

Why Choose Chuangbo Black Hard Anodize Aluminum Roller

Established in 2010, Ruian Chuangbo Machinery Co., Ltd. has specialized in manufacturing high-quality machinery parts, earning a strong reputation in the industry. One of Chuangbo’s standout products is the Black Hard Anodize Aluminum Roller, designed to meet standards of performance and durability.

Superior Surface Hardness: Through advanced hard anodizing technology, the rollers achieve exceptional surface hardness, greatly enhancing wear resistance and extending their service life even in demanding working conditions.

Corrosion Resistance: The anodized layer protects the aluminum core from oxidation and chemical damage, making the rollers highly durable in various industrial environments.

Lightweight and Strong: Thanks to the aluminum core, these rollers are lightweight yet maintain high structural strength, helping improve machine efficiency and reduce overall system load.

High Precision Manufacturing: Chuangbo uses precision machining and strict quality control to ensure roller balance, surface smoothness, and dimensional accuracy, which are crucial for high-speed production lines.

Smooth and Stable Operation: The hard anodized surface reduces friction, ensuring smoother operation and reducing material scratches or product defects during processing.

Customizable Options: Chuangbo offers customization in size, surface treatment, and other specifications, allowing the rollers to be perfectly adapted to different machines and applications.

Proven Industry Expertise: With over a decade of experience, Chuangbo is trusted by customers worldwide for delivering reliable, high-performance machinery parts at competitive prices.

Choosing Chuangbo Black Hard Anodize Aluminum Rollers means investing in durability, precision, and performance — ensuring your machinery runs more efficiently and with less downtime.

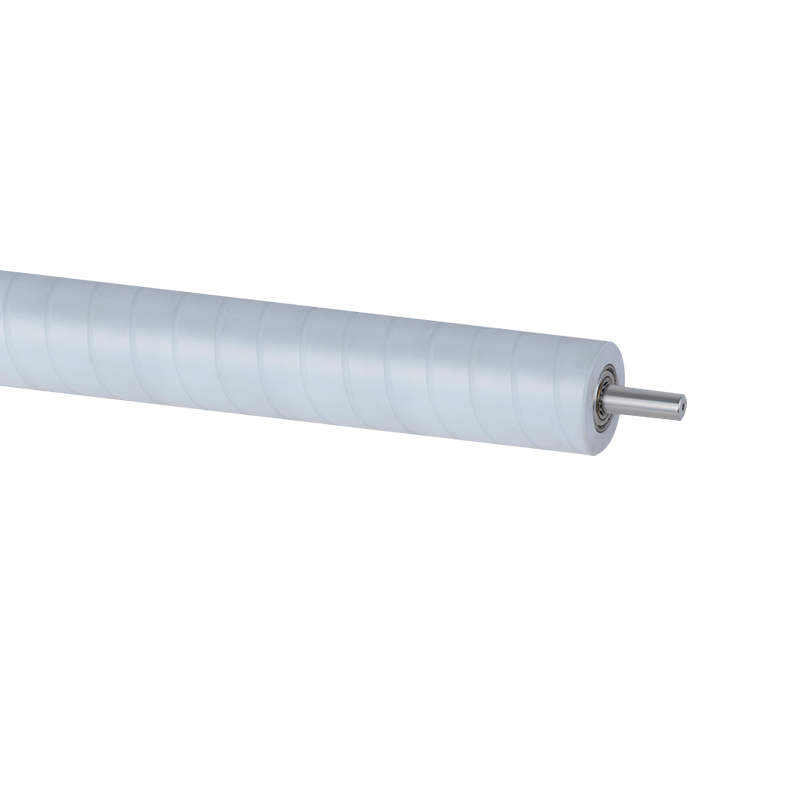

Soft Anodize Aluminum Roller

Soft Anodize Aluminum Roller

Aluminium Oxidetitanium Oxide Aluminum Roller

Aluminium Oxidetitanium Oxide Aluminum Roller

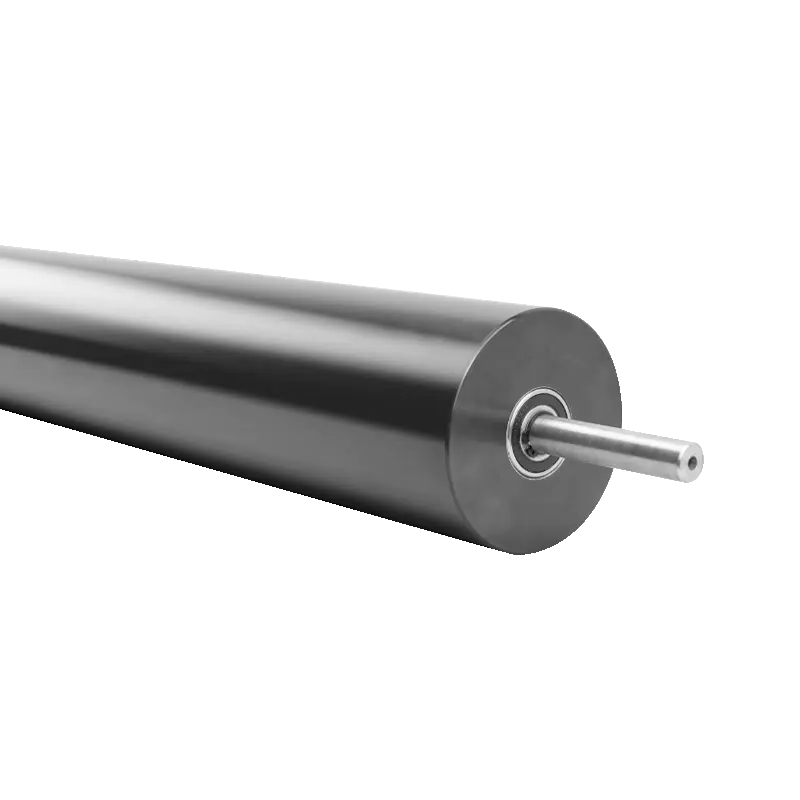

Hard Anodize Aluminum Roller

Hard Anodize Aluminum Roller

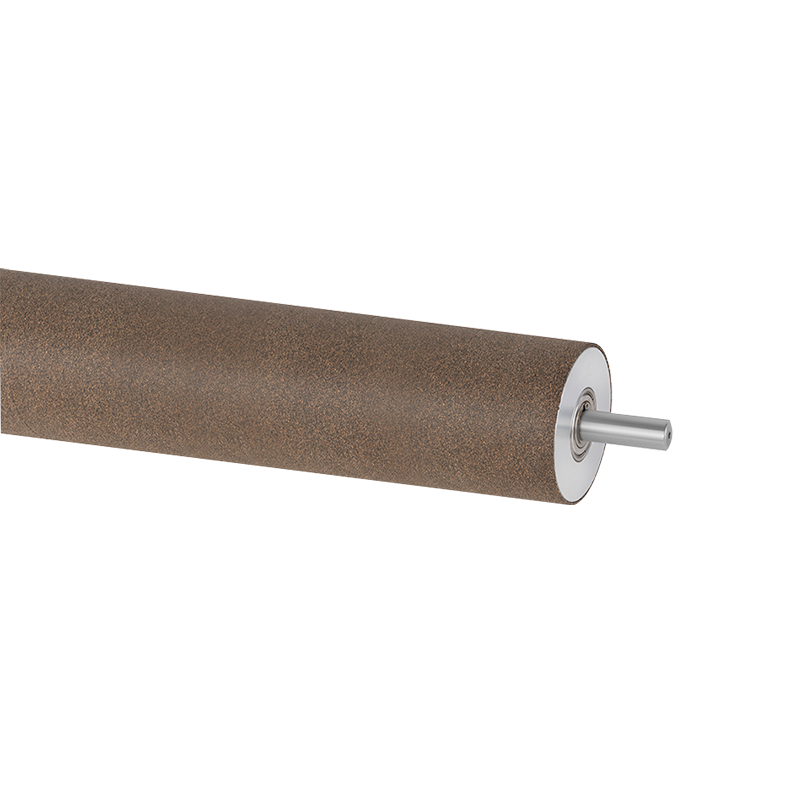

Cork Wrap Aluminum Roller

Cork Wrap Aluminum Roller

Black Hard Anodize Aluminum Roller

Black Hard Anodize Aluminum Roller

Micro Arc Oxidation Aluminum Roller

Micro Arc Oxidation Aluminum Roller

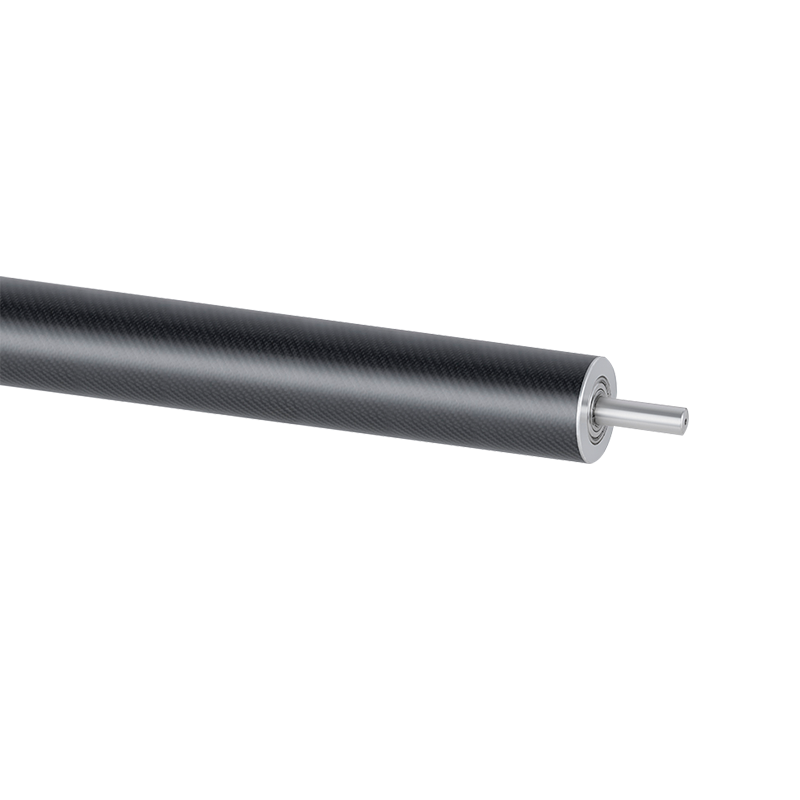

Carbon Fiber Roller Aluminum Roller

Carbon Fiber Roller Aluminum Roller

Plasma Alloy Anti-Sticking Aluminum Roller

Plasma Alloy Anti-Sticking Aluminum Roller

Hard Chrome Coating Aluminum Roller

Hard Chrome Coating Aluminum Roller

Soft Anodize Hv300 With Sandblasting Aluminum Roller

Soft Anodize Hv300 With Sandblasting Aluminum Roller

Hard Anodize Hv700 With Sandblasting Aluminum Roller

Hard Anodize Hv700 With Sandblasting Aluminum Roller

Customizable Aluminum Roller

Customizable Aluminum Roller