Ruian Chuangbo Machinery Co., Ltd. is specialized in manufacturing of Plasma Alloy Anti-Sticking Aluminum Roller .

-

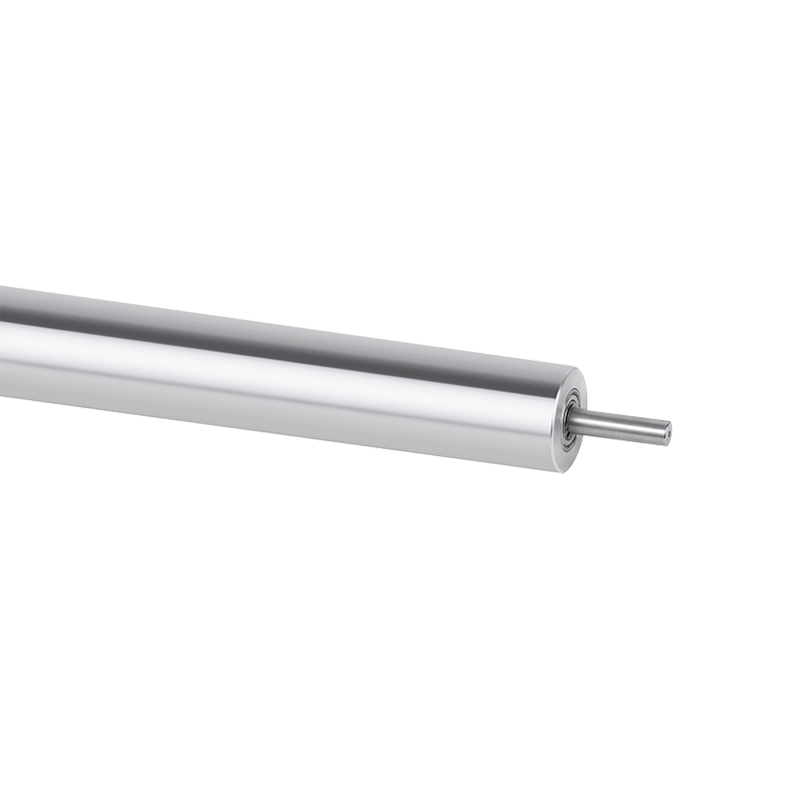

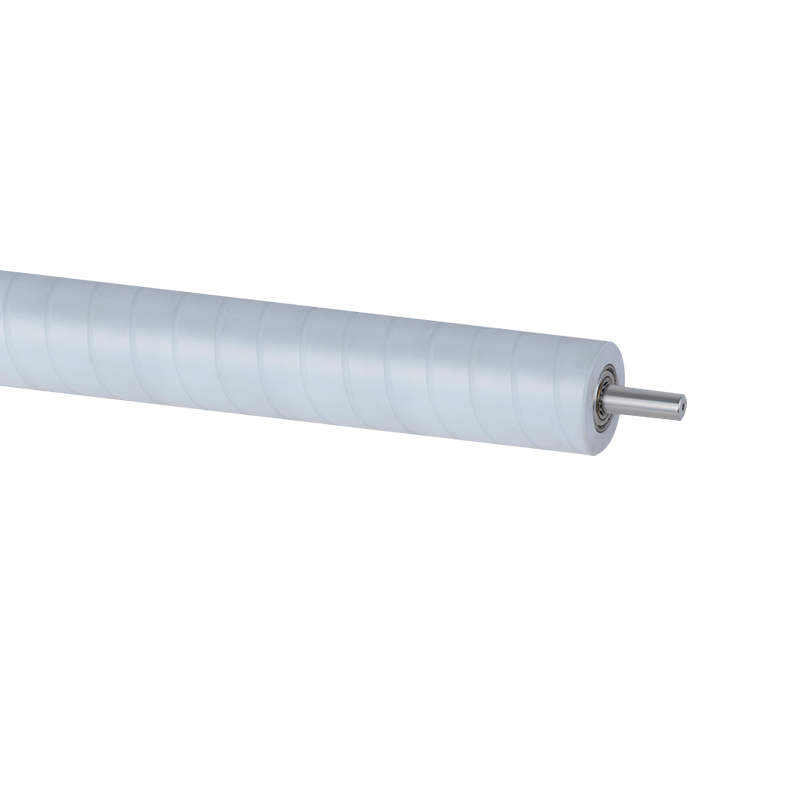

Soft Anodize Aluminum Roller

Soft Anodize Aluminum Roller

-

Aluminium Oxidetitanium Oxide Aluminum Roller

Aluminium Oxidetitanium Oxide Aluminum Roller

-

Hard Anodize Aluminum Roller

Hard Anodize Aluminum Roller

-

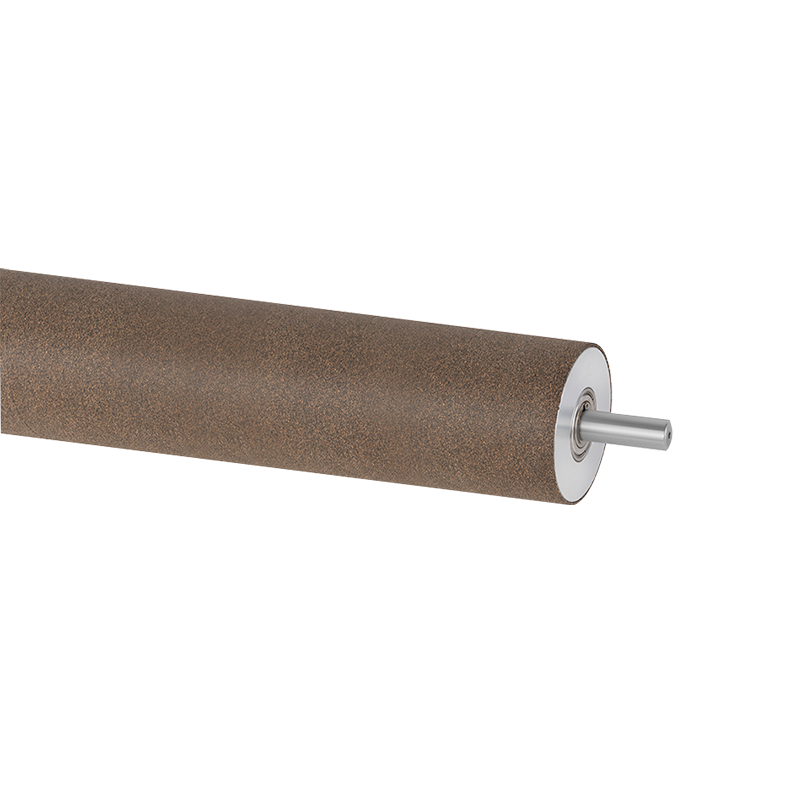

Cork Wrap Aluminum Roller

Cork Wrap Aluminum Roller

-

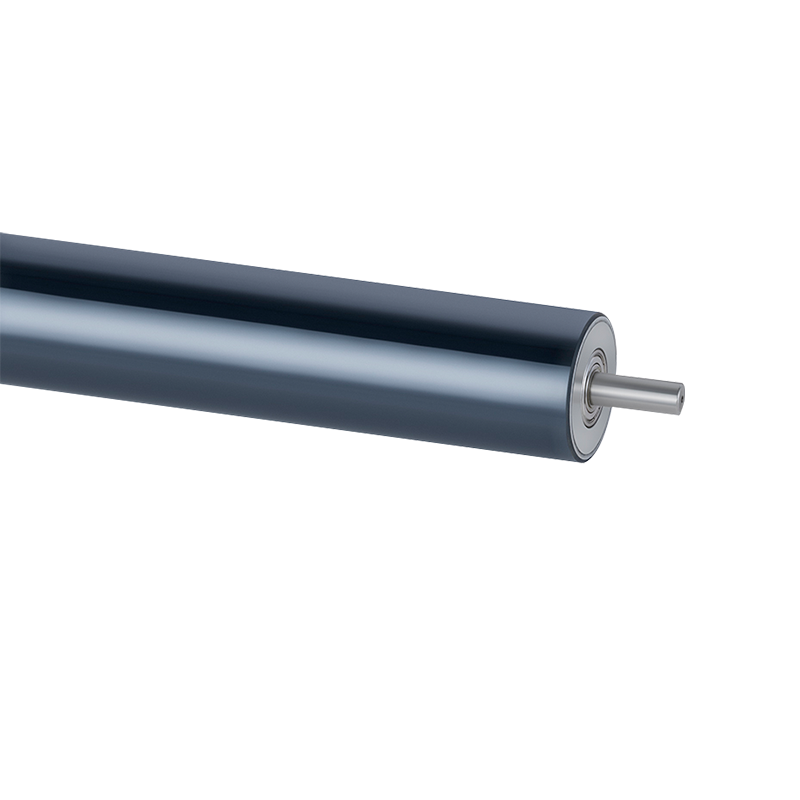

Black Hard Anodize Aluminum Roller

Black Hard Anodize Aluminum Roller

-

Micro Arc Oxidation Aluminum Roller

Micro Arc Oxidation Aluminum Roller

-

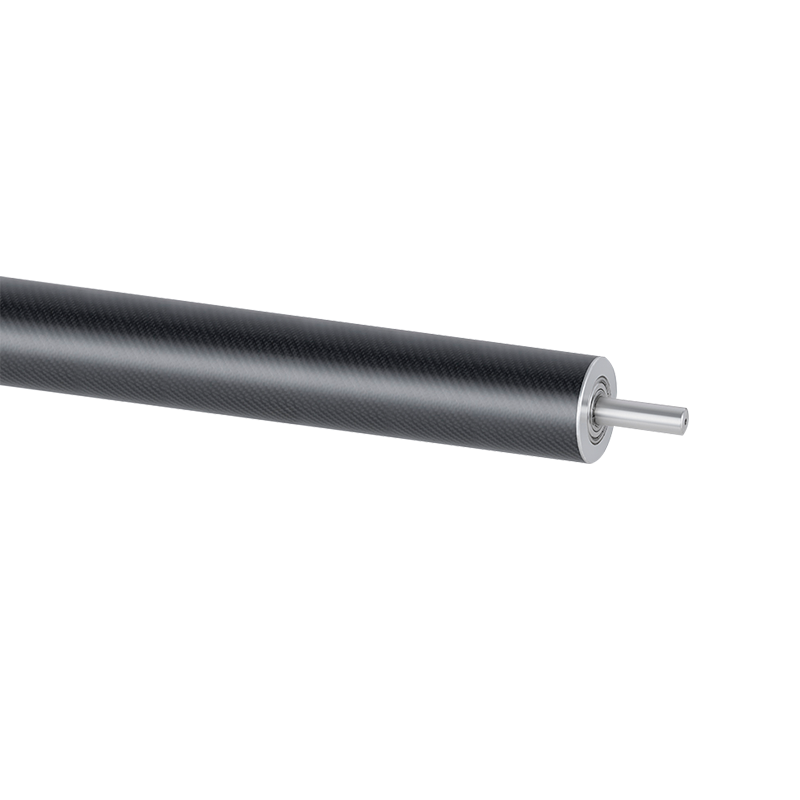

Carbon Fiber Roller Aluminum Roller

Carbon Fiber Roller Aluminum Roller

-

Plasma Alloy Anti-Sticking Aluminum Roller

Plasma Alloy Anti-Sticking Aluminum Roller

-

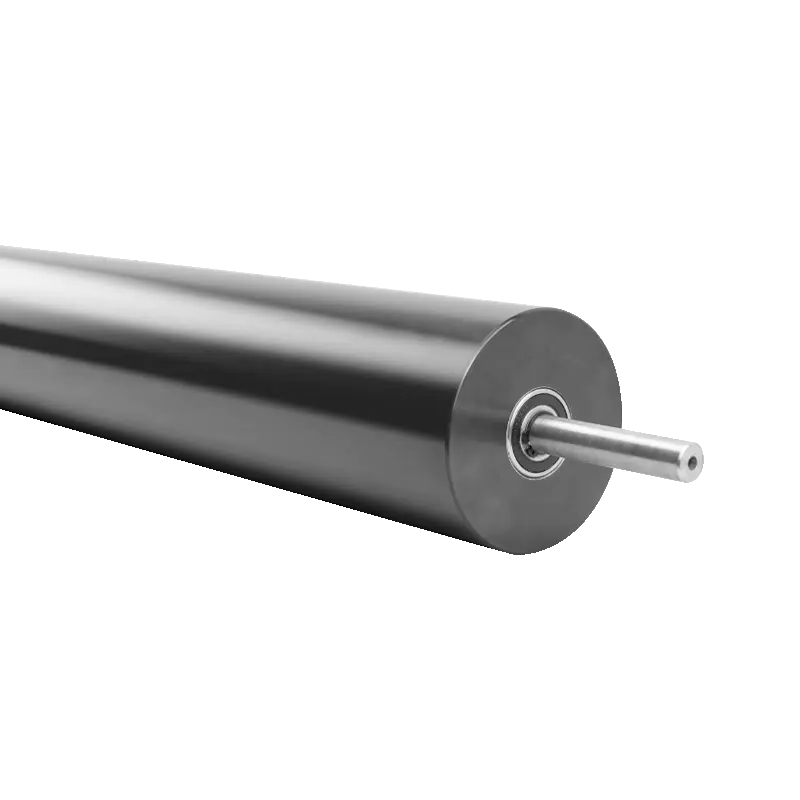

Hard Chrome Coating Aluminum Roller

Hard Chrome Coating Aluminum Roller

-

Soft Anodize Hv300 With Sandblasting Aluminum Roller

Soft Anodize Hv300 With Sandblasting Aluminum Roller

-

Hard Anodize Hv700 With Sandblasting Aluminum Roller

Hard Anodize Hv700 With Sandblasting Aluminum Roller

-

Customizable Aluminum Roller

Customizable Aluminum Roller