Soft anodized aluminum rollers are a specialty product used across a wide range of industries for their durability and corrosion resistance. Through the anodizing process, a protective oxide layer is formed on the surface of the aluminum. This oxide layer provides many benefits, including increased resistance to environmental damage such as corrosion and wear, while maintaining the lightweight properties of aluminum. This article will take a closer look at the key features, benefits and common applications of soft anodized aluminum rollers.

What is soft anodizing?

Soft anodizing is an electrolytic process that improves the properties of aluminum by thickening its natural oxide layer. The process involves immersing the aluminum part in an electrolytic bath and applying an electric current, which forms an oxide layer on the surface. Unlike hard anodizing, which produces a thicker and more abrasive coating, soft anodizing produces a relatively thin oxide layer. The process enhances the surface properties of the aluminum without significantly affecting its appearance or weight.

Key Features of Soft Anodized Aluminum Rollers

Soft anodized aluminum rollers offer a variety of unique properties that make them suitable for a wide range of applications. These properties include enhanced durability, smooth surface quality, and corrosion resistance.

Corrosion resistance: The anodized coating significantly improves the roller's ability to resist corrosion, maintaining performance even when exposed to harsh chemicals or moisture. This makes soft anodized aluminum rollers ideal for industries where equipment may come into contact with corrosive substances, ensuring long-term use without performance degradation.

Smooth surface finish: The anodizing process creates a smooth and uniform surface, which reduces friction during operation. This is particularly important in industries such as printing and spraying, where precision and consistency are critical. The smoothness of the roller also minimizes wear and tear on other components, thereby increasing the overall efficiency and life of the equipment.

Lightweight and durable: Aluminum itself is a lightweight material, which helps reduce the weight of the roller. Despite the thin protective coating, soft anodizing also enhances the durability of the material, making it suitable for long-term use. The roller is able to withstand the demands of continuous operation and is not easily worn, helping companies avoid frequent roller replacement and reduce operating costs.

Aesthetics: Another benefit of soft anodizing is that aluminum rollers are available in a wide variety of colors. The anodized surface is porous and can be dyed, allowing manufacturers to choose the appearance of the roller based on their brand or design preferences. This aesthetic flexibility makes these rollers particularly useful in consumer-facing industries.

Automotive and Aerospace: The automotive and aerospace industries use soft anodized aluminum rollers in a variety of manufacturing processes. These industries require equipment that can withstand high-stress environments and maintain high performance. The lightweight nature of aluminum combined with the durability provided by the anodizing process reduces maintenance costs: The corrosion resistance of the anodized coating means that soft anodized aluminum rollers are less expensive to maintain than uncoated rollers. They are not susceptible to rust or other forms of corrosion, reducing the need for regular repairs or replacement.

Energy Efficiency: Since aluminum is a lightweight material, soft anodized aluminum rollers help improve energy efficiency in the production process. The reduced weight of the roller means less power is required to operate, which helps improve the energy efficiency of the system.

Customization: The anodizing process allows for customization of the roller in terms of functionality and appearance. The porous nature of the anodized surface enables the addition of a variety of colors, while the smooth surface ensures that the roller will function effectively in a variety of applications.

Conclusion

Soft anodized aluminum rollers offer many advantages, including increased durability, corrosion resistance, and a smooth surface. These rollers are essential components for a variety of industries, including printing, spraying, material handling, food processing, and automotive. Choose soft anodized aluminum rollers, customization: The anodizing process allows for customization of the roller in terms of functionality and appearance. The porous nature of the anodized surface enables the addition of a variety of colors, while the smooth surface ensures that the roller will function effectively in a variety of applications.

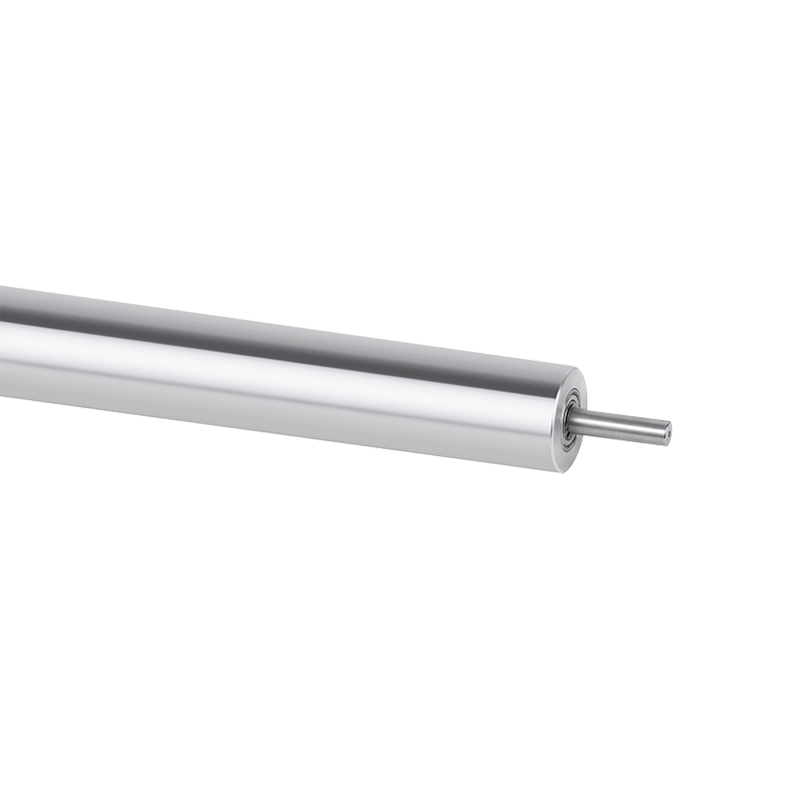

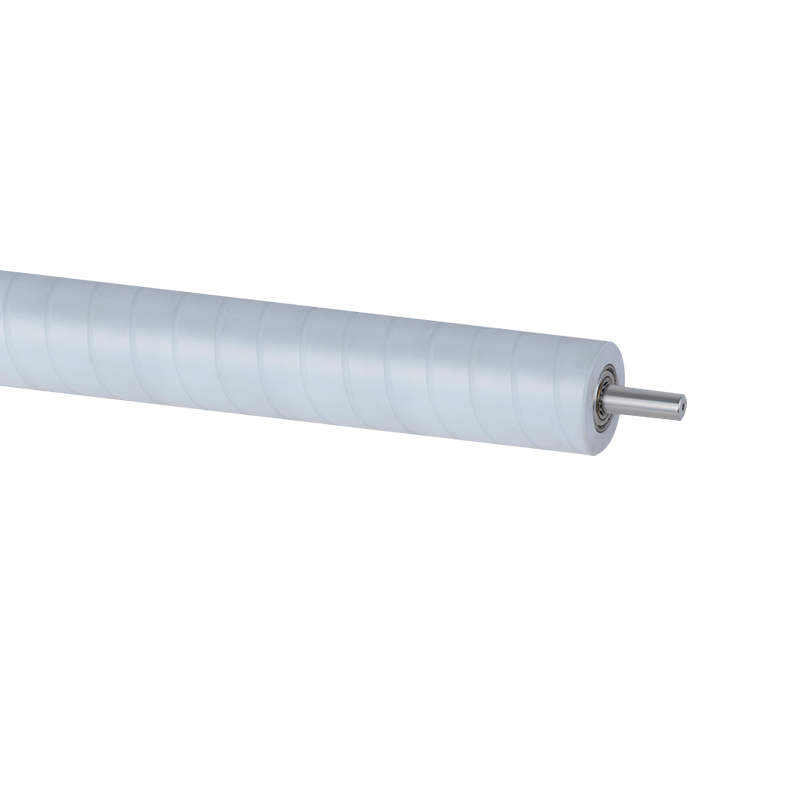

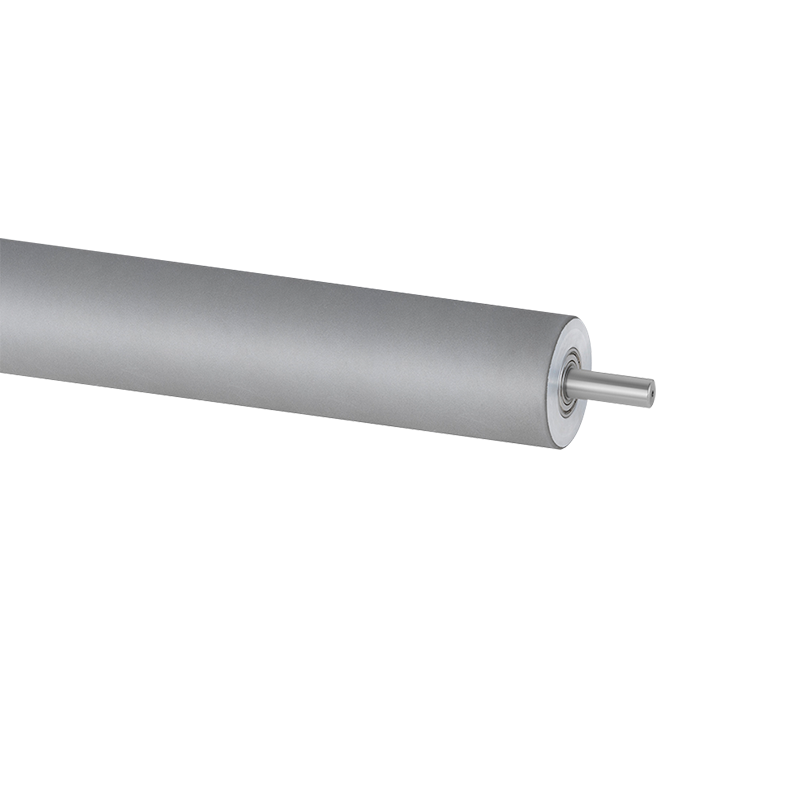

Soft Anodize Aluminum Roller

Soft Anodize Aluminum Roller

Aluminium Oxidetitanium Oxide Aluminum Roller

Aluminium Oxidetitanium Oxide Aluminum Roller

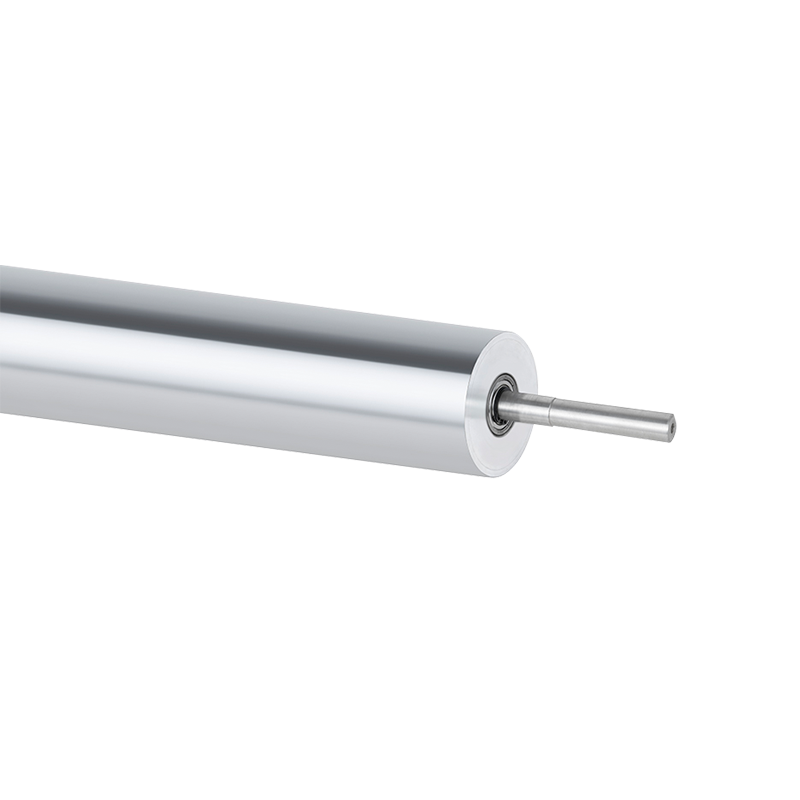

Hard Anodize Aluminum Roller

Hard Anodize Aluminum Roller

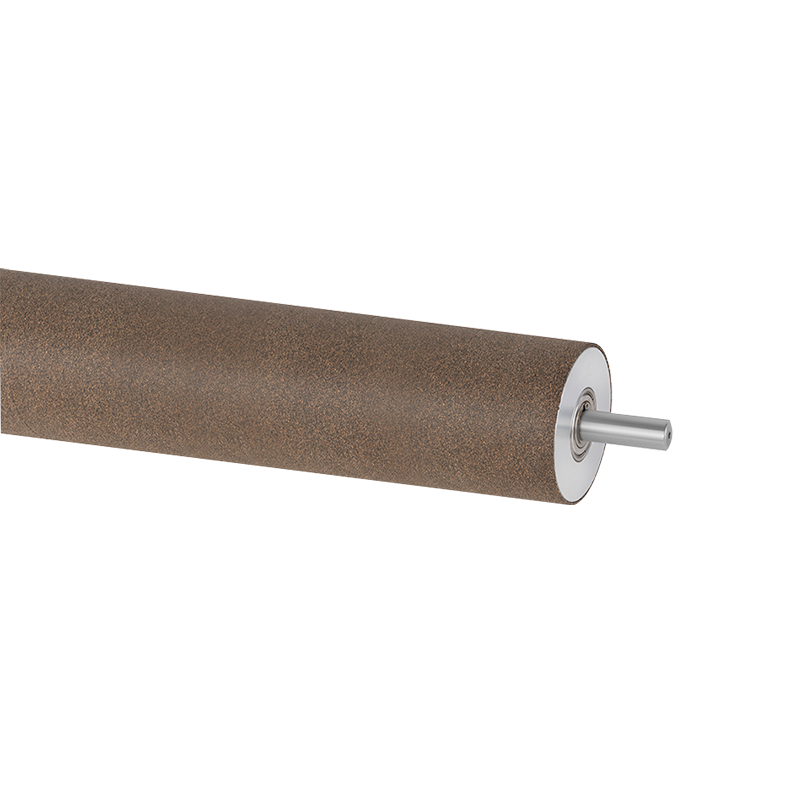

Cork Wrap Aluminum Roller

Cork Wrap Aluminum Roller

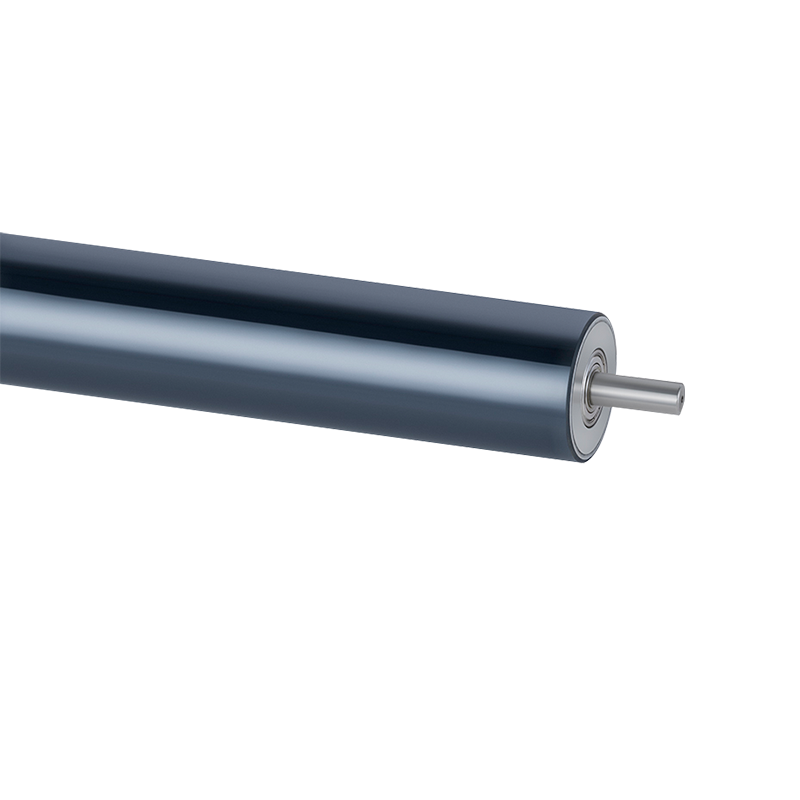

Black Hard Anodize Aluminum Roller

Black Hard Anodize Aluminum Roller

Micro Arc Oxidation Aluminum Roller

Micro Arc Oxidation Aluminum Roller

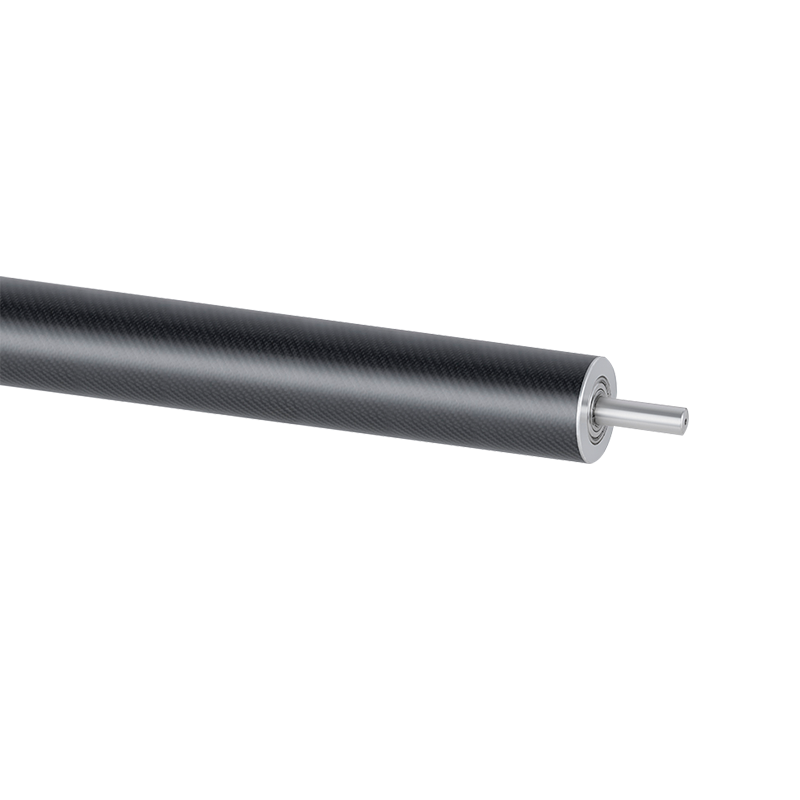

Carbon Fiber Roller Aluminum Roller

Carbon Fiber Roller Aluminum Roller

Plasma Alloy Anti-Sticking Aluminum Roller

Plasma Alloy Anti-Sticking Aluminum Roller

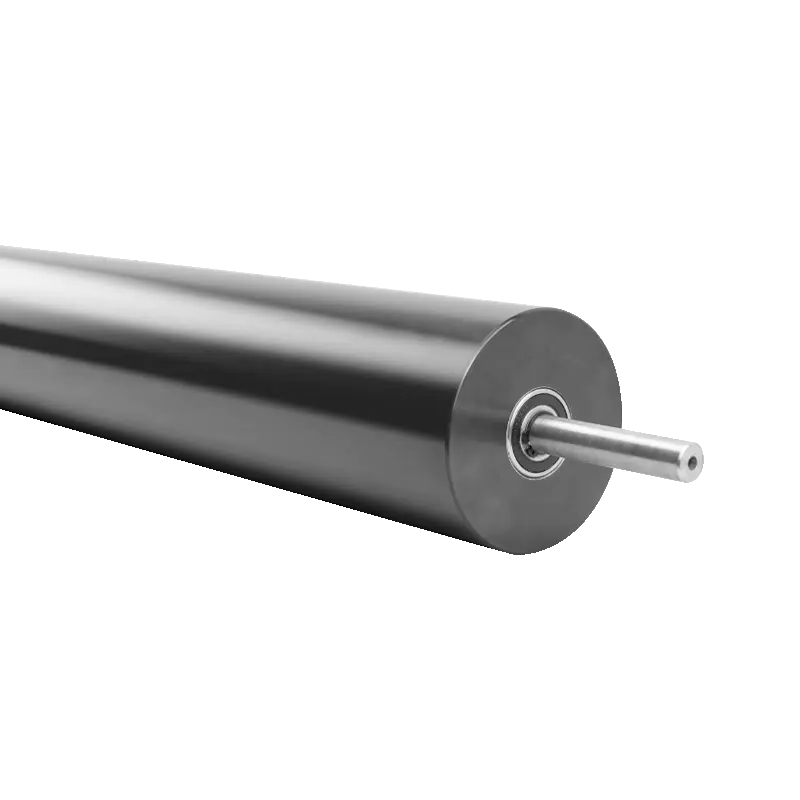

Hard Chrome Coating Aluminum Roller

Hard Chrome Coating Aluminum Roller

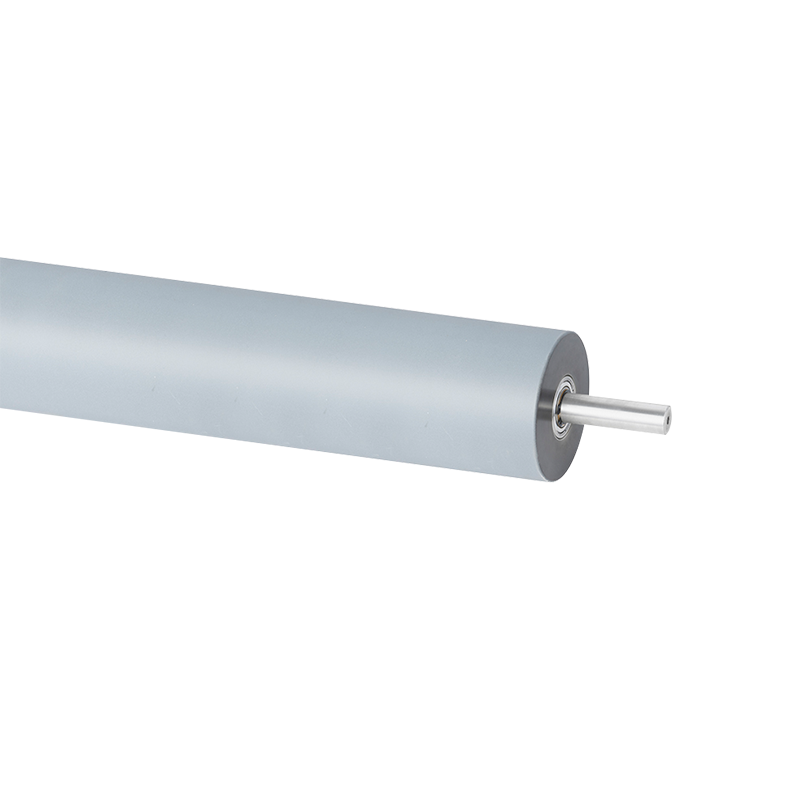

Soft Anodize Hv300 With Sandblasting Aluminum Roller

Soft Anodize Hv300 With Sandblasting Aluminum Roller

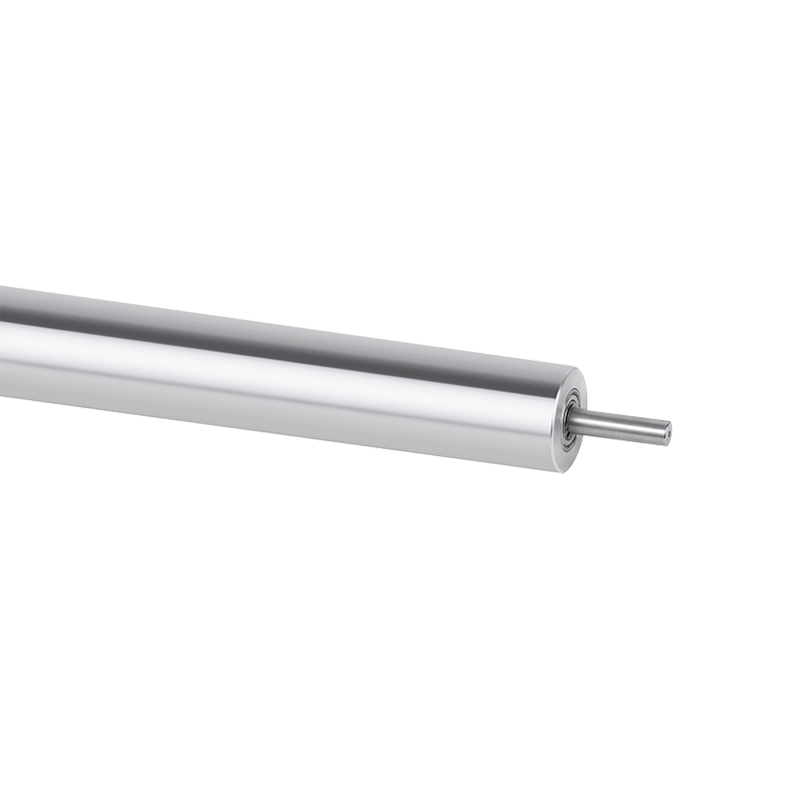

Hard Anodize Hv700 With Sandblasting Aluminum Roller

Hard Anodize Hv700 With Sandblasting Aluminum Roller

Customizable Aluminum Roller

Customizable Aluminum Roller