Alumina/titania aluminum rollers are advanced and durable components that combine the benefits of both aluminum oxide and titanium oxide coatings. These rollers are used in a wide variety of industrial applications due to their hardness, corrosion resistance, and ability to withstand environments. By combining the two oxides, the surface properties of the rollers are enhanced, providing wear resistance and durability, making them ideal for high-performance applications across a wide range of industries. In this article, we will explore the key features of these rollers, the manufacturing process, and their wide range of applications.

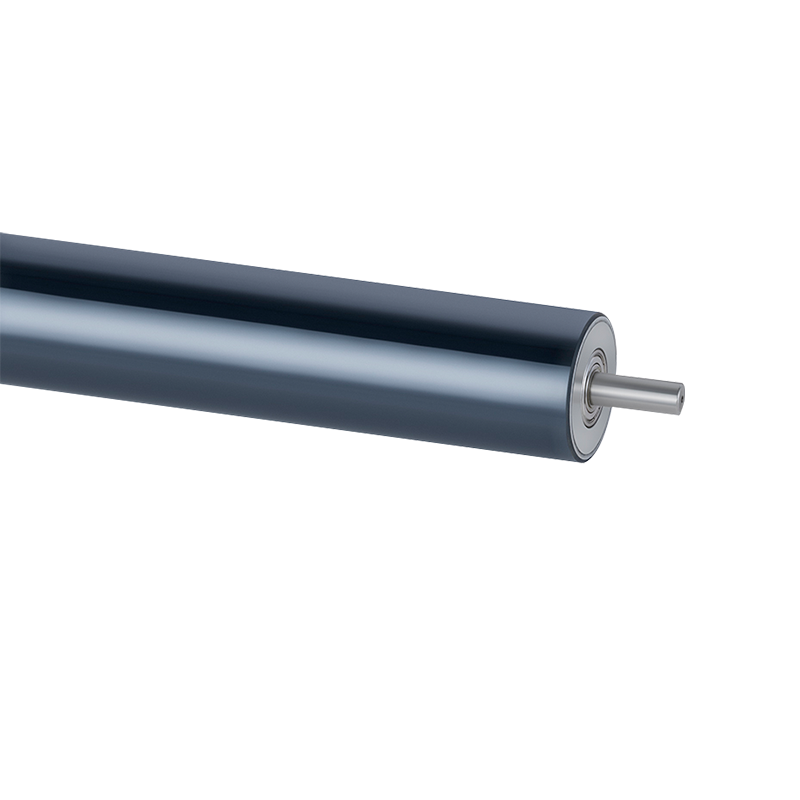

Enhanced Durability: One of the outstanding features of aluminum oxide/titania aluminum rollers is their durability. The dual oxide coating provides wear resistance, allowing the rollers to continue to be used in demanding applications. The hardness of aluminum oxide and titanium oxide ensures that the rollers maintain their functionality and do not show significant performance degradation over time.

High Temperature Resistance: Titanium oxide is known for its ability to withstand temperatures. When applied to aluminum rollers, the coating enhances their heat resistance, allowing them to function properly in high temperature environments without compromising their structural integrity. This makes them ideal for industries that require equipment to operate reliably even in high temperature conditions.

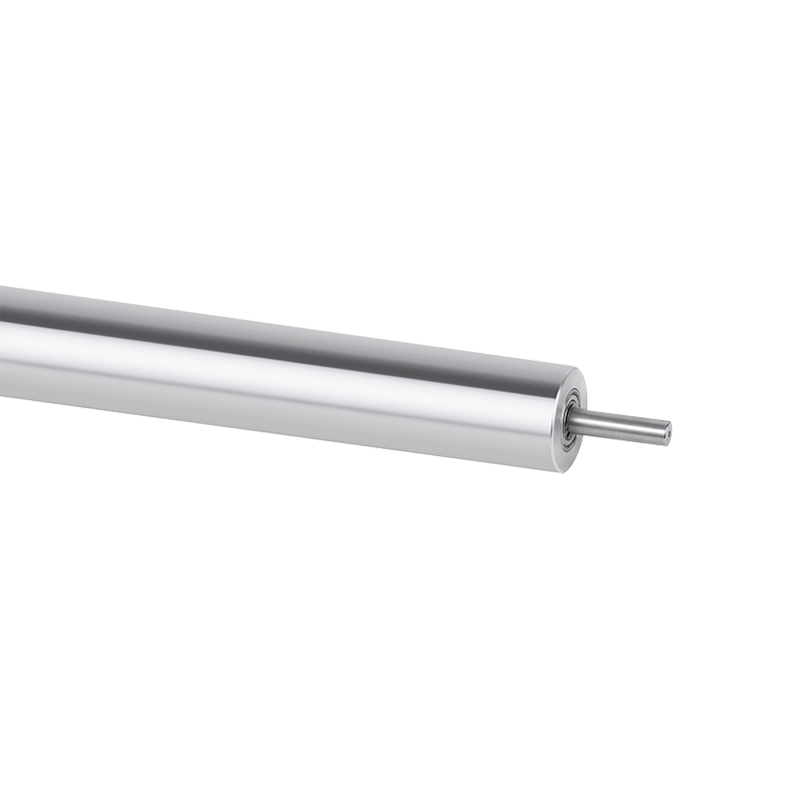

Smooth Surface Finish: The oxide coating is applied using an anodizing process that creates a smooth and consistent surface. This reduces friction during operation, which is particularly beneficial for industries such as printing, spraying and material handling that require smooth and efficient movement. The reduction in friction also helps prevent wear on other mechanical parts, ensuring that the system operates at a higher efficiency.

Lightweight Strength: Despite the addition of the coating, aluminum oxide/titanium oxide aluminum rollers retain the inherent lightweight properties of aluminum. This makes them easier to handle and easy to integrate into a machine or production line without adding unnecessary weight. The strength provided by the oxide coating ensures that the roller can withstand the mechanical stress of its environment, while its lightweight properties help optimize overall operating efficiency.

Key Features of Aluminum Oxide/Titanium Oxide Aluminum Rollers

Excellent Wear Resistance: The addition of aluminum oxide and titanium oxide to the surface of aluminum rollers creates a highly wear-resistant coating. This makes these rollers ideal for industries that require parts to withstand constant friction and mechanical stress without performance degradation over time.

High Temperature Resistance: Titanium dioxide is known for its high temperature resistance and stable performance. This makes Aluminum Oxide/Titania Aluminum Rollers particularly suitable for industries that need to work in high temperature environments.

Reduced Maintenance Costs: Due to their corrosion resistance and durability, Aluminum Oxide/Titania Aluminum Rollers have lower maintenance costs than standard aluminum rollers. The protective coating helps prevent rust, corrosion and wear, which means that businesses can save on maintenance costs in the long term.

Aluminum Oxide/Titania Aluminum Rollers are ideal for industries that require durable, high-performance parts. Their wear, corrosion, heat resistance and smooth running properties make them ideal for applications such as printing, spraying, material handling, food processing, automotive manufacturing, and aerospace. These rollers offer many benefits, including longer service life, lower maintenance costs, and higher operating efficiency. Aluminum Oxide/Titania Aluminum Rollers provide a rugged and reliable solution. adoption into existing systems.

By integrating hard anodization technology with precision aluminum engineering, this roller delivers unmatched performance and reliability across industries. Its adaptability to diverse configurations and applications—from automotive manufacturing to renewable energy—ensures it is a strategic investment for businesses prioritizing productivity and cost efficiency.

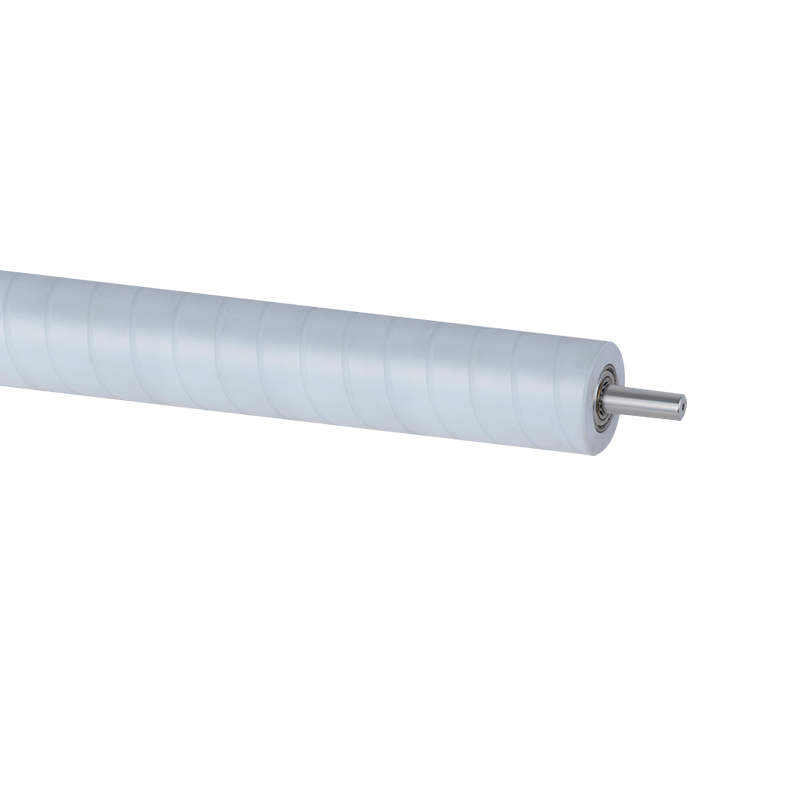

Soft Anodize Aluminum Roller

Soft Anodize Aluminum Roller

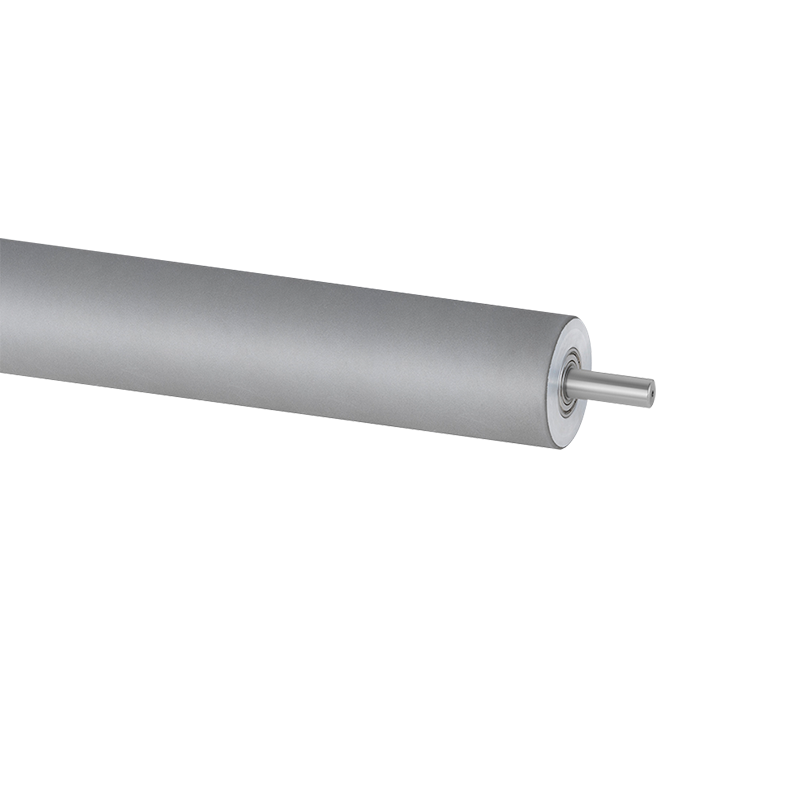

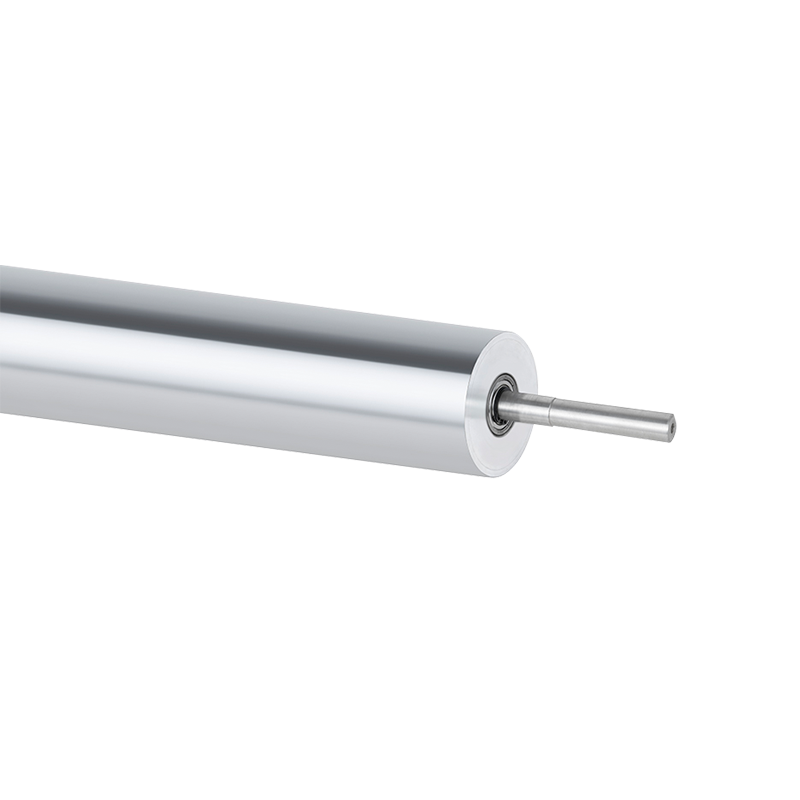

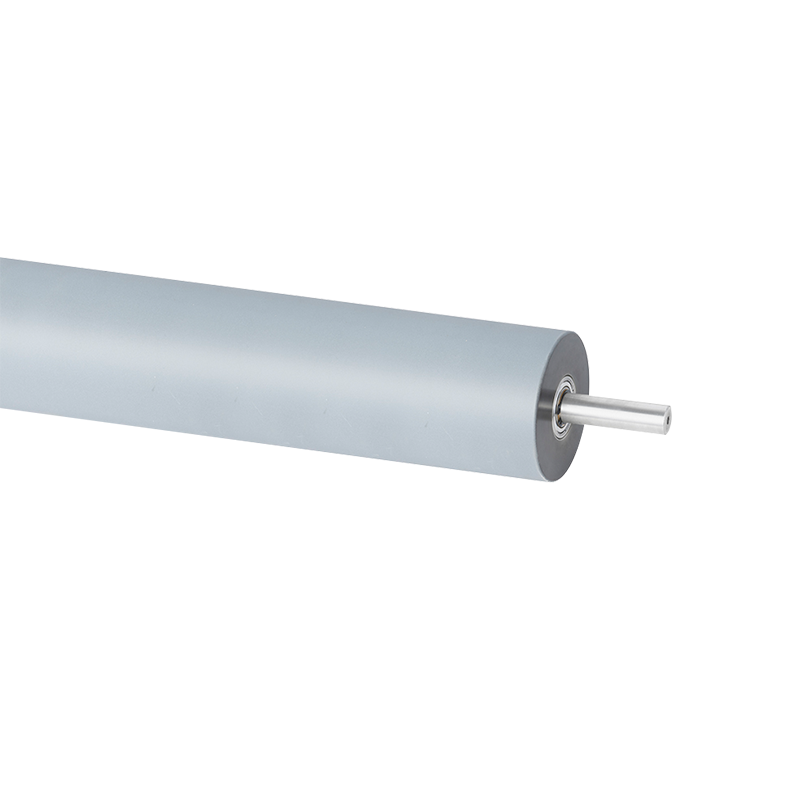

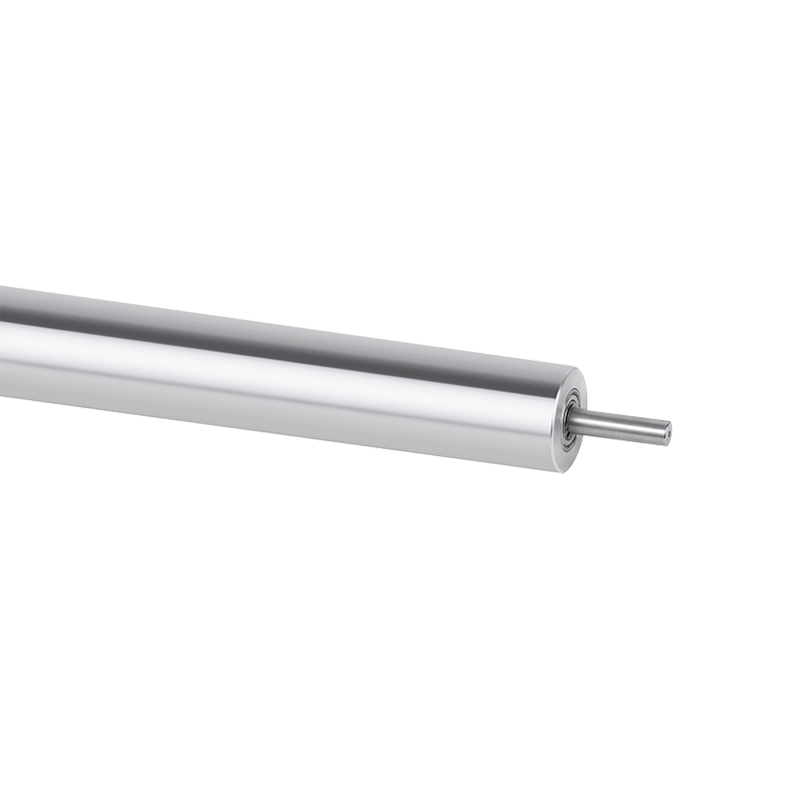

Aluminium Oxidetitanium Oxide Aluminum Roller

Aluminium Oxidetitanium Oxide Aluminum Roller

Hard Anodize Aluminum Roller

Hard Anodize Aluminum Roller

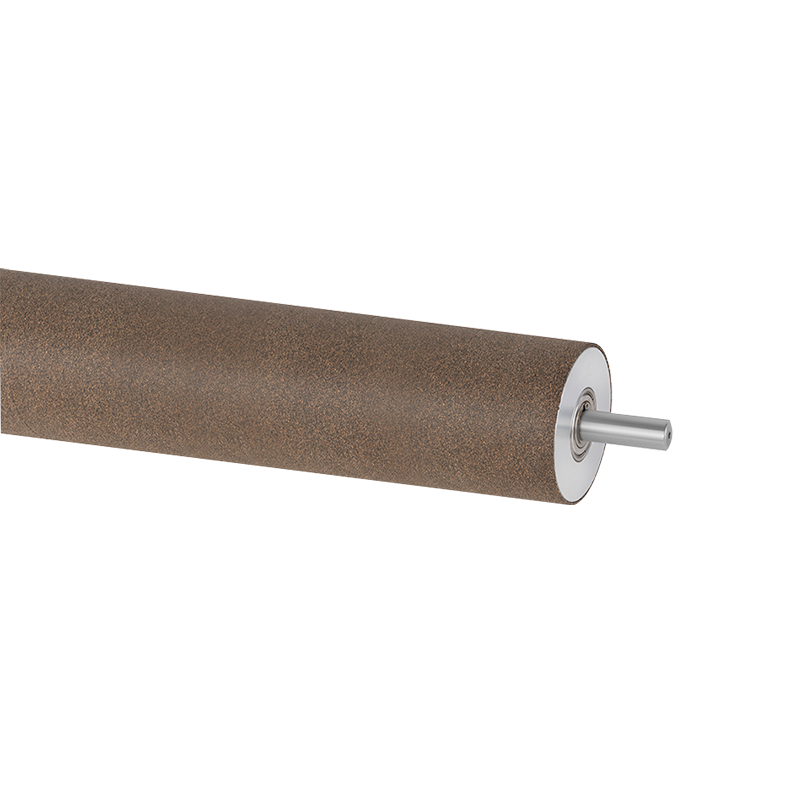

Cork Wrap Aluminum Roller

Cork Wrap Aluminum Roller

Black Hard Anodize Aluminum Roller

Black Hard Anodize Aluminum Roller

Micro Arc Oxidation Aluminum Roller

Micro Arc Oxidation Aluminum Roller

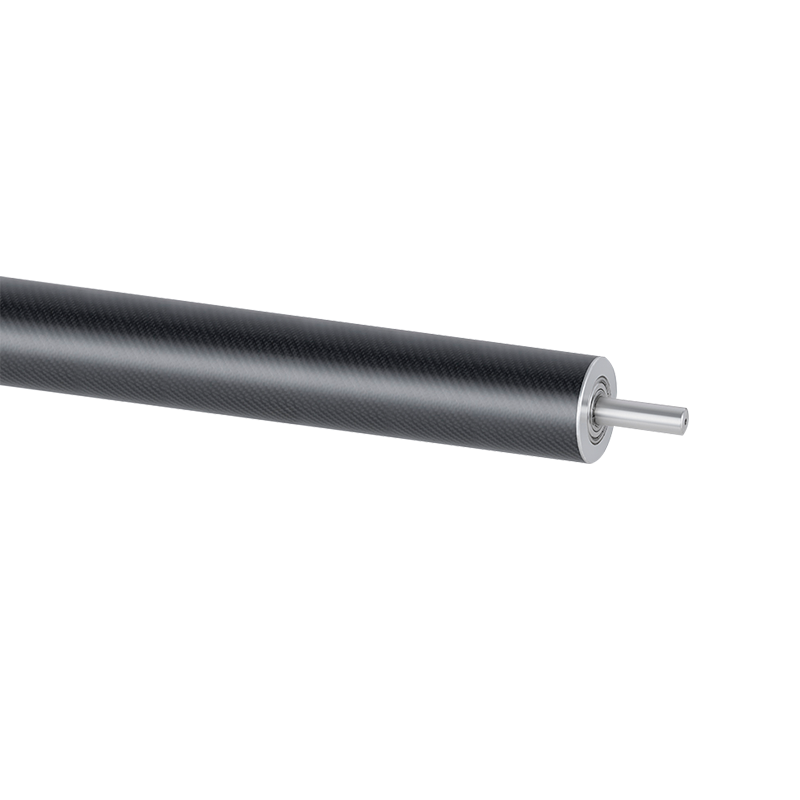

Carbon Fiber Roller Aluminum Roller

Carbon Fiber Roller Aluminum Roller

Plasma Alloy Anti-Sticking Aluminum Roller

Plasma Alloy Anti-Sticking Aluminum Roller

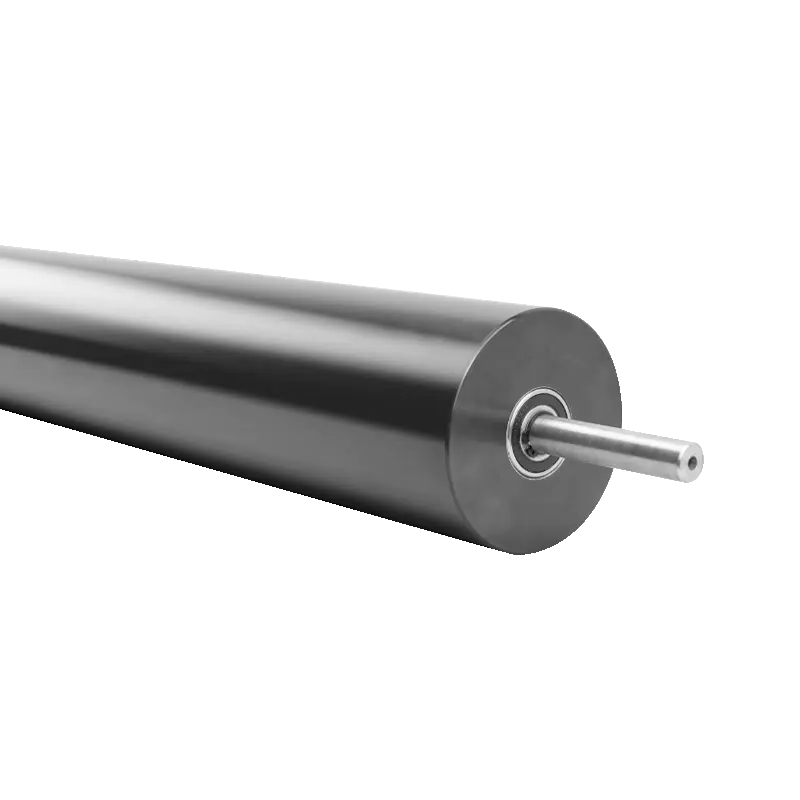

Hard Chrome Coating Aluminum Roller

Hard Chrome Coating Aluminum Roller

Soft Anodize Hv300 With Sandblasting Aluminum Roller

Soft Anodize Hv300 With Sandblasting Aluminum Roller

Hard Anodize Hv700 With Sandblasting Aluminum Roller

Hard Anodize Hv700 With Sandblasting Aluminum Roller

Customizable Aluminum Roller

Customizable Aluminum Roller